Layin Nika na CNC na Layin ...

1. Aikace-aikacen:

Layin samar da layin birki na CNC cikakke ne ta atomatik, galibi ana amfani da shi ne don sarrafa layin birki bayan an danna shi da zafi, gami da niƙa baka na ciki da na waje, ramukan haƙowa, layukan iyaka na niƙa, da sauransu.

2. Fa'idodinmu:

● Duk layin samarwa ya ƙunshi manyan wuraren aiki guda shida, duk ana sarrafa su ta hanyar tsarin sarrafa kansa na CNC. Wannan layin samarwa yana da cikakkun ayyuka kuma yana da sauƙin aiki. Ana iya gyara duk sigogin sarrafawa ta hanyar allon taɓawa akan harsashi na waje, kuma ma'aikata kawai suna buƙatar shigar da bayanai na umarni cikin kwamfutar.

● Layin samarwa yana kuma da tsarin lodawa da sauke kaya ta atomatik, wanda ke kawar da buƙatar sanya takardar hannu da kuma ƙara yawan aikin samarwa.

● Wannan layin samarwa ya dace da manyan tsare-tsaren samarwa na samfura daban-daban, kuma layin samarwa guda ɗaya zai iya samar da guda 2000 bisa ga lokacin aiki na awanni takwas a kowane aiki.

3. Siffofin tashoshin aiki:

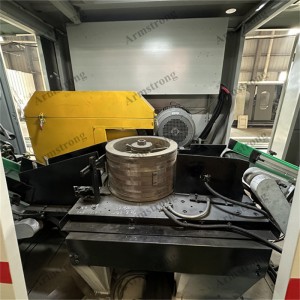

3.1 Injin Nika Mai Tsauri Na Waje

3.1.1 Ana sanya jikin injin da aka haɗa da walda, farantin ƙarfe mai kauri mm 40 (babban farantin ɗaukar kaya) da farantin ƙarfe mai kauri mm 20 (haƙarƙarin ƙarfafawa) na tsawon kwanaki 15 na aiki bayan walda, sannan a kawar da damuwar walda ta hanyar girgizar na'urar girgiza mai tasiri ga lokaci, don haka tsarin zai daidaita.

3.1.2 Za a iya maye gurbin cibiyar tayoyin cikin mintuna 15, yana da sauri don canza samfuri.

3.1.3 Kawai sai a maye gurbin molds daban-daban domin sarrafa guda-guda masu kauri iri ɗaya da marasa daidaito.

3.1.4 An samar da ma'aunin maganadisu na nunin dijital don daidaita ƙafafun ƙafa da motsin ƙafafun, tare da daidaiton nuni na 0.005mm.

3.1.5 Tayar niƙa tana amfani da fasahar lu'u-lu'u mai siffar electroplated, tare da babban girman niƙa. Diamita na tayar niƙa shine 630mm, kuma faɗin saman niƙa shine 50mm.

3.1.6 Tayar niƙa tana da murfin cire ƙura daban, tare da tasirin cire ƙura sama da 90%. Injin yana da cikakken shinge don ƙara ware ƙura, kuma an sanya na'urar cire ƙura da tattarawa.

3.2 Injin Nika na Cikin Baki

3.2.1 Wannan injin yana haɗa ayyuka da yawa na niƙawa a kusa da ƙarshen fuska, niƙa baka na ciki, da kuma tsaftace tokar baka na ciki.

3.2.2 Lodawa ta atomatik, mannewa da silinda. Ana iya daidaita tsayi da faɗin na'urar ciyarwa da sauri. Yana iya daidaitawa da takamaiman bayanai na layin birki ba tare da canza mold ba.

3.2.3 Na'urar niƙa gefen tana amfani da ƙafafun niƙa guda biyu waɗanda injinan sauri ke tuƙawa don niƙa ɓangarorin biyu na layin birki a lokaci guda, tare da babban gudu mai layi, sarrafa daidaito, niƙa mai ƙarfi, ƙaramin girgiza da kuma daidaiton sarrafawa mai yawa. A lokacin niƙa, ana gyara layin birki kuma an manne shi a ɓangarorin biyu na toshewar wuri, kuma ana manne silinda na hydraulic na gaba da na baya don iyakance canjin layin birki da kuma shafar daidaito. Ana amfani da silinda na hydraulic don tuƙa bencin aiki, don motsi ya tabbata kuma hatsin niƙa ya daidaita. Ɗauki dabarar niƙa kan namomin kaza mai siffar lu'u-lu'u don niƙa. Daidaita ƙafafun niƙa yana ɗaukar wurin zama mai zamiya, wanda za'a iya daidaita shi sama da ƙasa, gaba da baya, da kusurwa.

3.3 Injin Chamfering

3.3.1 Ana iya aiwatar da ayyuka da yawa kamar su chamfering, inner arc da other arc surface cleaning, da sauransu.

3.3.2 Kowace hanya tana amfani da na'urar cire ƙura da aka rufe don cire ƙurar da aka samar, wanda hakan ke samar da tsabta da kuma sarrafa kansa.

3.3.3 A kowane mataki na ciyarwa, samfurin ba zai tsaya a matsayin keken chamfering da keken goge yashi don guje wa tsayawa na dogon lokaci da kuma shafar ingancin samfurin ba.

3.4 Injin hakowa

3.4.1 Daidaiton injina: Zare 5-10 (Matsayin ƙasa shine zare 15-30)

3.4.2 Faɗin sarrafawa da ingantaccen aiki mai kyau:

Yana iya sarrafa faifan birki da Max.width: 225mm, R142~245mm, diamita na ramin haƙa rami 10.5~23.5mm.

3.4.3 Ma'aikaci ɗaya zai iya sarrafa injina 3-4, injina ɗaya (awanni 8) zai samar da guda 1000-3000 na birki.

3.5 Injin Nika Mai Kyau na Wucin Gadi

3.5.1 Jikin walda yana amfani da farantin ƙarfe mai kauri mm 40 (babban farantin ɗaukar kaya), farantin ƙarfe mai kauri mm 20 (haƙarƙarin ƙarfafawa), sannan a sanya shi na tsawon kwanaki 15 na aiki bayan walda. Sannan, ana yin girgiza ta hanyar na'urar girgiza mai tasiri don kawar da damuwar walda da kuma daidaita tsarin.

3.5.2 Ana iya cire cibiyar a maye gurbinta cikin mintuna 15.

3.5.3 Kawai sai a maye gurbin molds daban-daban domin sarrafa kauri iri ɗaya da wanda bai daidaita ba.

3.5.4 Daidaitawar ƙafafun niƙa da motsi na cibiyar ƙafafun an sanye su da na'urar sarrafa grid mai maganadisu ta dijital, tare da daidaiton nuni na 0.005mm.

3.5.5 Tayar niƙa tana amfani da fasahar lu'u-lu'u mai siffar electroplated, tare da layukan niƙa masu kyau da diamita na mm 630. An samar da tayar niƙa mai naɗi don niƙa ta waje da kyau, don tabbatar da cewa layukan niƙa ta waje iri ɗaya ne da ta ciki.

3.6 Injin Nika Layin Iyaka

3.6.1 Wannan samfurin ya yi amfani da fasahar niƙa kai da yawa, wanda zai iya niƙa girman gefe da layin iyaka na layin birki a lokaci guda, kuma zai iya zaɓar sarrafa ɗaya daga cikinsu.

3.6.2 Silinda ta iska tana tura layin birki cikin na'urar yayin lodi. Akwai na'urorin jagora na numfashi da sanyawa a ɓangarorin biyu na cibiyar don sa layin birki ya manne da na'urar ba tare da canza yanayin ba.

3.6.3 Tayar niƙa tana amfani da dabaran niƙa lu'u-lu'u mai siffar lantarki.

3.6.4 Tayar niƙa tana sarrafa faɗin ko iyakar layin birki a lokaci guda.

3.6.5 Haɗa kayayyaki a kan cibiyar ƙafafun, sannan a canza nau'in samfurin. Sai dai ana buƙatar maye gurbin kayayyaki masu dacewa.

3.6.6 An gyara ƙafafun niƙa da wani abin zamiya mai layi biyu, wanda za a iya daidaita shi da kuma motsa shi a hanyoyi biyu. Kowace daidaitawa tana da na'urar sanya nuni ta dijital wacce ke da daidaiton nuni na 0.01 mm.

3.6.7 An haɗa ɓangaren wutar lantarki da matsayin tallafi da farantin ƙarfe mai kauri mm 30. Ƙara wani shinge da aka rufe gaba ɗaya a cikin kayan aikin don ƙara ware ƙura, sannan a sanya na'urar tsotsa da tattara ƙura.