CNC Nres Lining Post Grinding Line

1. Daim Ntawv Thov:

CNC nres kab ntau lawm kab yog tag nrho automatic yog siv rau kev ua tiav ntawm nres kab tom qab kub nias, suav nrog kev sib tsoo sab hauv thiab sab nraud arcs, drilling qhov, sib tsoo txwv kab, thiab lwm yam.

2. Peb Cov Zoo:

● Tag nrho cov kab ntau lawm muaj rau lub chaw ua haujlwm tseem ceeb, txhua yam tswj hwm los ntawm CNC automation systems. Cov kab ntau lawm no muaj cov haujlwm tiav thiab yooj yim rau kev khiav lag luam. Txhua yam kev ua haujlwm tuaj yeem hloov kho los ntawm cov ntxaij vab tshaus kov ntawm lub plhaub sab nraud, thiab cov neeg ua haujlwm tsuas yog xav tau cov ntaub ntawv hais kom ua rau hauv lub khoos phis tawj.

● Cov kab ntau lawm kuj muaj lub tshuab thauj khoom thiab tshem tawm tsis siv neeg, uas tshem tawm qhov xav tau kev tso daim ntawv tes thiab ua kom muaj txiaj ntsig zoo tshaj plaws.

● Cov kab ntau lawm no tsim nyog rau cov phiaj xwm tsim khoom loj ntawm cov qauv ib tus zuj zus, thiab ib kab ntau lawm tuaj yeem tsim tau 2000 daim raws li lub sijhawm ua haujlwm yim teev rau ib lub sijhawm ua haujlwm.

3. Cov chaw ua haujlwm nta:

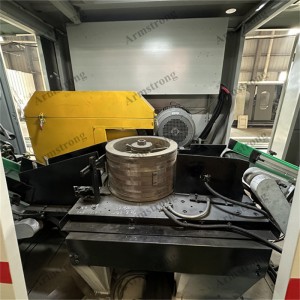

3.1 Tshuab Sib Tsoo Arc Sab Nraud

3.1.1 Lub cev tshuab vuam, 40 hli tuab hlau phaj (lub phaj tseem ceeb) thiab 20 hli tuab hlau phaj (reinforcing tav) raug muab tso rau 15 hnub ua haujlwm tom qab vuam, thiab tom qab ntawd qhov kev ntxhov siab vuam raug tshem tawm los ntawm kev co ntawm lub vibrator uas siv sijhawm ntev, yog li ua rau cov qauv ruaj khov.

3.1.2 Lub log hub tuaj yeem hloov tau hauv 15 feeb, nws ceev rau kev hloov qauv.

3.1.3 Tsuas yog yuav tsum hloov cov pwm sib txawv kom ua tiav cov khoom sib npaug thiab tsis sib npaug.

3.1.4 Cov duab digital magnetic grating ruler yog muab rau kev hloov kho log thiab kev txav mus los ntawm log, nrog rau qhov tseeb ntawm 0.005mm.

3.1.5 Lub log sib tsoo siv cov thev naus laus zis pob zeb diamond electroplated, nrog rau qhov sib tsoo loj. Lub txoj kab uas hla ntawm lub log sib tsoo yog 630 hli, thiab qhov dav ntawm qhov sib tsoo yog 50 hli.

3.1.6 Lub log sib tsoo muaj lub hau tshem plua plav sib cais, nrog rau cov txiaj ntsig tshem plua plav ntau dua 90%. Lub tshuab muaj lub qhov kaw tag nrho kom cais cov plua plav ntxiv, thiab muaj lub cuab yeej rho thiab sau cov plua plav.

3.2 Tshuab Sib Tsoo Arc Sab Hauv

3.2.1 Lub tshuab no muaj ntau yam kev ua haujlwm ntawm kev sib tsoo qhov chaw kawg, kev sib tsoo sab hauv, thiab kev ntxuav cov tshauv sab hauv.

3.2.2 Tsis siv neeg loading, lub tog raj kheej clamping. Qhov ntev thiab dav ntawm lub cuab yeej pub mis tuaj yeem hloov kho sai. Nws tuaj yeem hloov kho rau ntau yam kev qhia tshwj xeeb ntawm cov ntaub thaiv nres yam tsis hloov pwm.

3.2.3 Lub cuab yeej sib tsoo ntug siv ob lub log sib tsoo uas tsav los ntawm cov cav ceev ceev los sib tsoo ob sab ntawm lub hauv paus nres tib lub sijhawm, nrog kev ceev ceev linear, kev ua tiav symmetrical, kev sib tsoo ruaj khov, kev co me me thiab kev ua tiav raug. Thaum sib tsoo, lub hauv paus nres raug kho thiab clamped los ntawm ob sab ntawm lub thaiv qhov chaw, thiab lub tog raj kheej hydraulic pem hauv ntej thiab tom qab raug clamped kom txwv qhov kev hloov pauv ntawm lub hauv paus nres thiab cuam tshuam rau qhov raug. Lub tog raj kheej hydraulic yog siv los tsav lub rooj ua haujlwm, yog li ntawd kev txav mus los ruaj khov thiab cov nplej sib tsoo yog sib npaug. Siv lub log sib tsoo taub hau pob zeb diamond electroplated rau kev sib tsoo. Kev hloov kho ntawm lub log sib tsoo siv lub rooj zaum dovetail swb, uas tuaj yeem hloov kho rau saum thiab nqis, pem hauv ntej thiab nraub qaum, thiab lub kaum sab xis.

3.3 Tshuab Txiav

3.3.1 Ntau yam txheej txheem xws li chamfering, sab hauv arc thiab sab nraud arc ntxuav nto, thiab lwm yam. Yuav ua tau tib lub sijhawm.

3.3.2 Txhua txoj kev siv lub tshuab rho plua plav kaw kom rho tawm cov plua plav uas tsim tawm, ua tiav kev tsim khoom huv si thiab tsis siv neeg.

3.3.3 Txhua kauj ruam ntawm kev pub mis, cov khoom yuav tsis nres ntawm qhov chaw ntawm lub log chamfering thiab lub log txhuam xuab zeb kom tsis txhob nyob twj ywm ntev thiab cuam tshuam rau qhov zoo ntawm cov khoom.

3.4 Tshuab Drilling

3.4.1 Kev ua haujlwm siab precision: 5-10 xov (Lub teb chaws tus qauv yog 15-30 xov)

3.4.2 Kev ua ntau yam thiab kev ua haujlwm zoo:

Nws tuaj yeem ua cov nres pads nrog Max.width: 225mm, R142 ~ 245mm, drilling qhov txoj kab uas hla 10.5 ~ 23.5mm.

3.4.3 Ib tug neeg ua haujlwm tuaj yeem ua haujlwm 3-4 lub tshuab, ib lub tshuab (8 teev) tuaj yeem tsim tau 1000-3000 daim ntawm cov ntaub nres.

3.5 Sab Nraud Arc Sib Tsoo Tshuab Zoo

3.5.1 Lub cev vuam siv lub phaj hlau tuab 40 hli (phaj tseem ceeb), phaj hlau tuab 20 hli (rib txhawb), thiab muab tso rau 15 hnub ua haujlwm tom qab vuam. Tom qab ntawd, kev co yog ua los ntawm lub vibrator uas siv sijhawm ntev kom tshem tawm kev ntxhov siab vuam thiab ruaj khov cov qauv.

3.5.2 Lub hub tuaj yeem raug tshem tawm thiab hloov pauv hauv 15 feeb.

3.5.3 Tsuas yog yuav tsum hloov cov pwm sib txawv kom ua tiav cov khoom sib npaug thiab tsis sib npaug.

3.5.4 Kev hloov kho ntawm lub log sib tsoo thiab kev txav mus los ntawm lub log hub yog nruab nrog lub ntsuas digital magnetic grid, nrog rau qhov tseeb ntawm 0.005mm.

3.5.5 Lub log sib tsoo siv cov thev naus laus zis pob zeb diamond electroplated, nrog cov kab sib tsoo zoo thiab txoj kab uas hla ntawm 630 hli. Lub log sib tsoo roller tau muab los sib tsoo cov arc sab nraud kom zoo, kom ntseeg tau tias cov kab sib tsoo arc sab nraud zoo ib yam li cov arc sab hauv.

3.6 Txwv Kab Sib Tsoo Tshuab

3.6.1 Tus qauv no siv ntau lub tshuab sib tsoo taub hau, uas tuaj yeem sib tsoo cov qhov ntev thiab kab txwv ntawm lub hauv paus nres tib lub sijhawm, thiab kuj tuaj yeem xaiv ua ib qho ntawm lawv.

3.6.2 Lub tog raj kheej cua thawb lub hauv paus nres rau hauv lub module thaum lub sijhawm thauj khoom. Muaj cov cuab yeej pneumatic kev taw qhia thiab qhov chaw nyob rau ob sab ntawm lub hub kom cov hauv paus nres lo rau lub module yam tsis muaj kev hloov pauv.

3.6.3 Lub log sib tsoo siv lub log sib tsoo pob zeb diamond electroplated.

3.6.4 Lub log sib tsoo ua tiav qhov dav lossis qhov txwv ntawm lub hauv paus nres tib lub sijhawm.

3.6.5 Muab cov modules sib dhos rau ntawm lub log hub, thiab hloov hom khoom. Tsuas yog cov modules sib xws xwb thiaj li yuav tsum tau hloov.

3.6.6 Lub log sib tsoo tau kho nrog lub slider dovetail hla, uas tuaj yeem hloov kho thiab txav mus rau ob qho kev taw qhia. Txhua qhov kev hloov kho kev taw qhia muaj lub cuab yeej tso saib digital nrog qhov tseeb ntawm 0.01 hli.

3.6.7 Lub zog fais fab thiab qhov chaw txhawb nqa tau vuam nrog 30 hli tuab hlau phaj. Ntxiv ib lub thawv kaw tag nrho rau cov khoom siv kom cais cov hmoov av ntxiv, thiab nruab ib lub cuab yeej nqus thiab sau cov hmoov av.