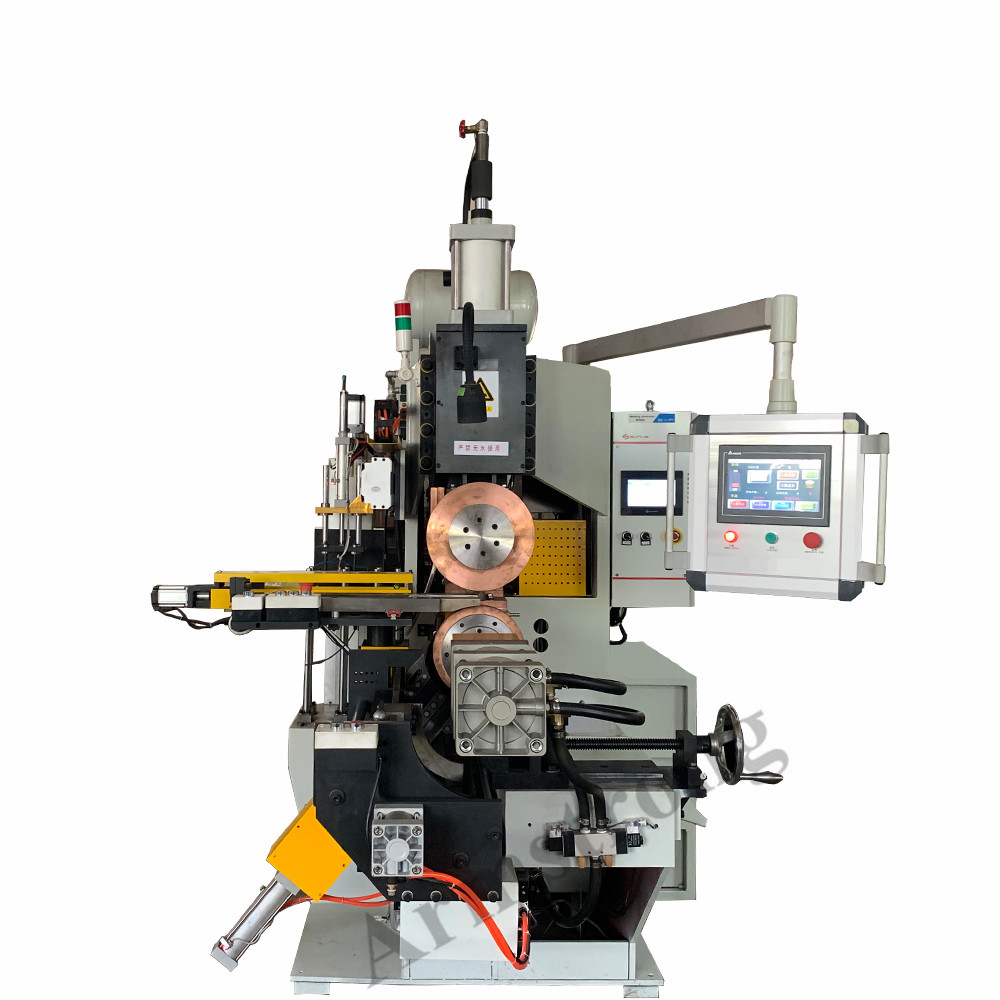

Makina Owotcherera Ozungulira A-BP400

Ntchito:

Kuwotcherera kwa roller, komwe kumadziwikanso kuti kuwotcherera kwa msoko wozungulira, ndi njira yomwe imagwiritsa ntchito ma electrode awiri ozungulira kuti alowe m'malo mwa ma electrode ozungulira a spot welding, ndipo ma workpiece olumikizidwawo amayenda pakati pa ma roll kuti apange sealing weld yokhala ndi ma nuggets olumikizana kuti awotchere ma workpiece. AC pulse current kapena amplitude modulation current nthawi zambiri imagwiritsidwa ntchito, ndipo ma DC current atatu (omwe ali ndi gawo limodzi), ma frequency apakati komanso ma frequency apamwamba angagwiritsidwenso ntchito. Kuwotcherera kwa roller kumagwiritsidwa ntchito kwambiri powotcherera ma thin plate a ma sealed containers mu ma drams amafuta, ma cani, ma radiator, ma tanki amafuta a ndege ndi magalimoto, ma rocket ndi ma missile. Nthawi zambiri, makulidwe a welding ali mkati mwa 3mm kuchokera pa single plate.

Nsapato ya mabuleki m'galimoto imapangidwa makamaka ndi mbale ndi nthiti. Nthawi zambiri timaphatikiza magawo awiriwa pogwiritsa ntchito njira yowotcherera, komanso makina owotcherera ma roller panthawiyi. Makina owotcherera ma roller apakati awa a nsapato ya mabuleki agalimoto ndi chida chabwino kwambiri chowotcherera chomwe chapangidwa ndikupangidwa ndi kampani yathu kuti chipange mabuleki agalimoto malinga ndi zofunikira zaukadaulo zowotcherera nsapato za mabuleki.

Zipangizozi zili ndi ntchito zosiyanasiyana ndipo ndizoyenera kulumikiza nsapato imodzi yolimbitsa mabuleki agalimoto. Chojambulira cha digito cha touch screen chimagwiritsidwa ntchito kuwongolera makonda ogwirira ntchito, zomwe ndi zosavuta komanso zosavuta kugwiritsa ntchito.

Zipangizo zowonjezera (chosungiramo zinthu za panel, bokosi loyendetsa, servo drive, clamping mold, pressure welding silinda) ndi zinthu zodziwika bwino padziko lonse lapansi. Kuphatikiza apo, planetary reducer yolondola kwambiri imatha kukonza kulondola kwa malo a nsapato.

Imagwiritsanso ntchito kompyuta yaying'ono ya chip imodzi ngati gawo lalikulu lowongolera, lomwe lili ndi mawonekedwe osavuta a circuit, kuphatikiza kwakukulu komanso luntha, limachepetsa kulephera ndipo ndi losavuta kukonza.

Gawo la kulumikizana ndi BCD code control function limalumikizidwa ndi makompyuta a mafakitale, PLC ndi zida zina zowongolera kuti zigwire ntchito yowongolera kutali komanso yowongolera yokha, zomwe zimapangitsa kuti ntchito ikhale yogwira bwino. 16 ma specifications a welding amatha kusungidwa kuti ogwiritsa ntchito azitcha malo oyambira.

Mafupipafupi otulutsa a chowongolera ma frequency apakati ndi 1kHz, ndipo malamulo apano ndi achangu komanso olondola, omwe sangatheke ndi makina wamba olumikizira ma frequency amphamvu.