Mzere Wopukutira wa CNC Brake Lining Post

1. Kugwiritsa ntchito:

Mzere wopangira mabuleki a CNC ndi wodzaza ndi makina odziyimira pawokha, womwe umagwiritsidwa ntchito makamaka pokonza mabuleki pambuyo powakanikiza motentha, kuphatikizapo kupukutira ma arcs amkati ndi akunja, mabowo obowola, mizere yochepetsera, ndi zina zotero.

2. Ubwino Wathu:

● Mzere wonse wopanga uli ndi malo ogwirira ntchito akuluakulu asanu ndi limodzi, onse olamulidwa ndi makina odziyimira pawokha a CNC. Mzere wopanga uwu uli ndi ntchito zonse ndipo ndi wosavuta kugwiritsa ntchito. Magawo onse opangira amatha kusinthidwa kudzera pazenera zogwira pa chipolopolo chakunja, ndipo ogwira ntchito amangofunika kuyika deta yamalamulo mu kompyuta.

● Mzere wopangira ulinso ndi makina olowetsa ndi kutsitsa okha, omwe amachotsa kufunika koyika mapepala pamanja ndikuwonjezera magwiridwe antchito opangira.

● Mzere wopangira uwu ndi woyenera kupanga mapulani akuluakulu a mitundu yosiyanasiyana, ndipo mzere umodzi wopangira ukhoza kupanga zidutswa 2000 kutengera nthawi yogwira ntchito ya maola asanu ndi atatu pa shift iliyonse.

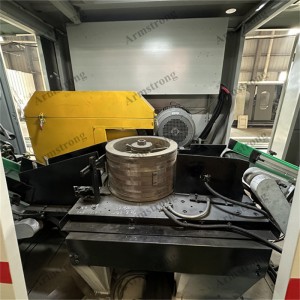

3. Malo ogwirira ntchito ali ndi zinthu izi:

3.1 Makina Opukutira Akunja a Coarse Arc

3.1.1 Thupi la makina olumikizidwa, mbale yachitsulo yokhuthala ya 40 mm (mbale yayikulu yonyamulira) ndi mbale yachitsulo yokhuthala ya 20 mm (nthiti yolimbitsa) zimayikidwa kwa masiku 15 ogwira ntchito mutagwiritsa ntchito cholumikizira, kenako kupsinjika kwa cholumikizira kumachotsedwa ndi kugwedezeka kwa vibrator yogwira ntchito nthawi, motero kumapangitsa kuti kapangidwe kake kakhale kokhazikika.

3.1.2 Chipinda cha mawilo chikhoza kusinthidwa mu mphindi 15, ndipo chimatha msanga kusintha mtundu.

3.1.3 Ndikofunikira kusintha nkhungu zosiyanasiyana kuti mugwiritse ntchito makulidwe ofanana komanso osafanana.

3.1.4 Chida chowongolera maginito chowonetsera cha digito chaperekedwa kuti chisinthe magudumu a mawilo ndi kuyenda kwa magudumu, ndi kulondola kwa chiwonetsero cha 0.005mm.

3.1.5 Gudumu lopukusira limagwiritsa ntchito ukadaulo wa diamondi wopangidwa ndi ma electroplated, wokhala ndi voliyumu yayikulu yopukusira. M'mimba mwake mwa gudumu lopukusira ndi 630mm, ndipo m'lifupi mwake pamwamba pa chopukusira ndi 50mm.

3.1.6 Gudumu lopukusira lili ndi chivundikiro chosiyana chochotsera fumbi, chokhala ndi mphamvu yochotsera fumbi yoposa 90%. Makinawa ali ndi malo otsekedwa bwino kuti atulutse fumbi, ndipo chipangizo chochotsera fumbi ndi kusonkhanitsa chimayikidwa.

3.2 Makina Opukutira Arc Yamkati

3.2.1 Makinawa amaphatikiza ntchito zosiyanasiyana monga kupukusa malo opumulira, kupukusa mkati mwa arc, ndi kuyeretsa phulusa la mkati mwa arc.

3.2.2 Kuyika zinthu zokha, kutsekereza silinda. Kutalika ndi m'lifupi mwa chipangizo chodyetsera zimatha kusinthidwa mwachangu. Chingathe kusintha malinga ndi zofunikira zosiyanasiyana za mabuleki popanda kusintha mawonekedwe.

3.2.3 Chipangizo chopera m'mphepete chimagwiritsa ntchito mawilo awiri opera omwe amayendetsedwa ndi ma mota othamanga kwambiri kuti agaye mbali zonse ziwiri za mzere wa mabuleki nthawi imodzi, ndi liwiro lalikulu, kukonza kofanana, kugaya kokhazikika, kugwedezeka pang'ono komanso kulondola kwambiri kwa kukonza. Pakugaya, mzere wa mabuleki umakhazikika ndikumangiriridwa ndi mbali zonse ziwiri za malo oimikapo, ndipo masilinda akutsogolo ndi akumbuyo a hydraulic amamangiriridwa kuti achepetse kusuntha kwa mzere wa mabuleki ndikukhudza kulondola. Silinda ya hydraulic imagwiritsidwa ntchito kuyendetsa benchi yogwirira ntchito, kuti kayendetsedwe kake kakhale kokhazikika ndipo njere yopera ikhale yofanana. Gwiritsani ntchito gudumu lopera mutu wa bowa la diamondi lomwe limakutidwa ndi electroplated kuti ligaye. Kusintha kwa gudumu lopera kumagwiritsa ntchito mpando wotsetsereka wa dovetail, womwe ungasinthidwe mmwamba ndi pansi, kutsogolo ndi kumbuyo, ndi ngodya.

3.3 Makina Opangira Chamfering

3.3.1 Njira zingapo monga kutsuka chitsulo, kuyeretsa chitsulo chamkati ndi chakunja, ndi zina zotero. Zingathe kuchitika nthawi imodzi.

3.3.2 Njira iliyonse imagwiritsa ntchito chipangizo chotseka chochotsera fumbi kuti ichotse fumbi lopangidwa, zomwe zimapangitsa kuti pakhale kupanga koyera komanso kodziyimira pawokha.

3.3.3 Pa sitepe iliyonse yoperekera chakudya, chinthucho sichiima pamalo pomwe pali gudumu lopukutira ndi gudumu lopukutira mchenga kuti chisatayike kwa nthawi yayitali ndikukhudza ubwino wa chinthucho.

3.4 Makina Obowolera

3.4.1 Kulondola kwambiri kwa makina: ulusi 5-10 (Muyezo wa dziko lonse ndi ulusi 15-30)

3.4.2 Kukonza zinthu zosiyanasiyana komanso kugwira ntchito bwino kwambiri:

Imatha kukonza ma brake pads ndi Max.width: 225mm, R142~245mm, dayamita la dzenje lobowola ndi 10.5~23.5mm.

3.4.3 Wantchito m'modzi akhoza kugwiritsa ntchito makina atatu kapena anayi, makina amodzi (maola 8) akhoza kupanga mabuleki okwana 1000-3000.

Makina Opukutira Abwino a Outer Arc 3.5

3.5.1 Thupi lolumikizidwa pogwiritsa ntchito mbale yachitsulo yokhuthala ya 40mm (mbale yayikulu yonyamulira), mbale yachitsulo yokhuthala ya 20mm (nthiti yolimbitsa), ndikuyiyika kwa masiku 15 ogwira ntchito mutagwiritsa ntchito cholumikizira. Kenako, kugwedezeka kumachitika ndi chovibrator chogwira ntchito nthawi kuti muchepetse kupsinjika kwa cholumikizira ndikukhazikitsa kapangidwe kake.

3.5.2 Chitolirocho chikhoza kuchotsedwa ndikusinthidwa mkati mwa mphindi 15.

3.5.3 Ndikofunikira kusintha nkhungu zosiyanasiyana kuti mugwiritse ntchito makulidwe ofanana komanso osafanana.

3.5.4 Kusintha kwa gudumu lopukusira ndi kayendedwe ka hub ya gudumu kuli ndi rula ya digito yowonetsera maginito, yokhala ndi kulondola kwa chiwonetsero cha 0.005mm.

3.5.5 Gudumu lopukusira limagwiritsa ntchito ukadaulo wa diamondi wopangidwa ndi ma electroplated, wokhala ndi mizere yopukusira yopyapyala komanso mainchesi 630. Gudumu lopukusira lozungulira limaperekedwa kuti lipukulitse bwino arc yakunja, kuonetsetsa kuti mizere yopukusira yakunja ndi yofanana ndi arc yamkati.

3.6 Makina Opukutira Mzere Wocheperako

3.6.1 Chitsanzochi chimagwiritsa ntchito ukadaulo wambiri wopukutira mutu, womwe nthawi imodzi umatha kupukutira miyeso ya mbali ndi malire a mzere wa brake, komanso ungasankhe kukonza chimodzi mwa izo.

3.6.2 Silinda ya mpweya imakankhira mkati mwa brake mu module panthawi yokweza. Pali zida zowongolera mpweya ndi zoyikiramo mbali zonse ziwiri za hub kuti ma brake agwirizane ndi module popanda kusuntha pang'ono.

3.6.3 Gudumu lopukusira limagwiritsa ntchito gudumu lopukusira la diamondi lopangidwa ndi electroplated.

3.6.4 Gudumu lopukusira limakonza nthawi imodzi m'lifupi kapena malire a brake.

3.6.5 Konzani ma module pa wheel hub, ndikusintha mtundu wa chinthucho. Ma module ogwirizana okha ndi omwe ayenera kusinthidwa.

3.6.6 Gudumu lopukusira limakhazikika ndi chotchingira chopingasa, chomwe chingasinthidwe ndikusunthidwa mbali ziwiri. Kusintha kulikonse kwa mbali kumakhala ndi choyimilira chowonetsera cha digito chokhala ndi kulondola kwa chiwonetsero cha 0.01 mm.

3.6.7 Gawo lamagetsi ndi malo othandizira zimalumikizidwa ndi mbale yachitsulo yokhuthala ya 30mm. Onjezani chitseko chotsekedwa bwino ku chipangizocho kuti muchotse fumbi, ndikuyika chipangizo chokoka ndi kusonkhanitsa fumbi.