Mashiinka daabacaadda laser-ka ee fiber-ka ah ee Laser Engraver

Codsiga:

Aqoonsiga iyo raadraaca badeecada: Mashiinka calaamadaynta laysarka ee khadka tooska ah wuxuu si toos ah u qori karaa lambarka taxanaha badeecada, lambarka dufcadda, taariikhda wax soo saarka iyo macluumaad kale oo ku yaal dusha sare ee badeecada, isagoo gaaraya aqoonsiga badeecada iyo raadraaca. Tani waxay muhiimad weyn u leedahay xakamaynta tayada, adeegga iibka kadib, iyo la socodka badeecada.

Ka-hortagga been abuurka iyo raadraaca: Tiknoolajiyada calaamadaynta laysarka waxay gaari kartaa calaamado yar oo ay adag tahay in lagu daydo alaabada, waxaana lagu dabaqi karaa dhinacyada ka-hortagga been abuurka iyo raadraaca. Si loo hubiyo saxnimada iyo badbaadada bareegyada biriiga.

Calaamadaynta qaybaha: Mashiinnada calaamadaynta laysarka waxay calaamadayn karaan qaybaha badeecada si loo fududeeyo dabagalka iyo maaraynta.

Faa'iidooyinka:

Wax soo saar hufan: Naqshadeynta khadka isku-dubaridka waxay u suurtagelinaysaa mashiinka calaamadaynta laysarka inuu si habsami leh ugu xidhmo khadka wax soo saarka, isagoo gaaraya calaamadaynta badeecada oo joogto ah. Marka la barbar dhigo calaamadaynta gacanta ama mashiinnada calaamadaynta ee si gaar ah loo shaqeeyo, waxay si weyn u horumarin kartaa hufnaanta wax soo saarka waxayna si dhakhso ah u dhammaystiri kartaa hawlaha calaamadaynta.

Hawlgalka otomaatiga ah: Mashiinka calaamadaynta laysarka ee khadka isku xidhka waxaa lagu dari karaa qalabka otomaatiga ah si loo gaaro hawlgal otomaatig ah oo dhammaystiran, taasoo badbaadinaysa waqtiga iyo kharashka shaqada ee hawlgalka gacanta. Shaqaaluhu waxay u baahan yihiin oo keliya inay badeecada saaraan suunka gudbiyaha, habka calaamadaynta oo dhanna si toos ah ayuu u dhammaystiraa mishiinku.

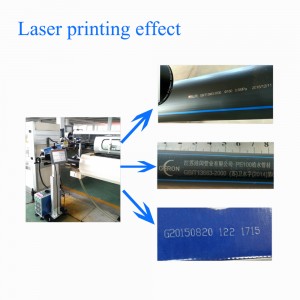

Calaamadaynta Saxda ah: Tiknoolajiyada calaamadaynta laysarka waxay leedahay saxnaan iyo xasillooni aad u sarreysa, taasoo gaari karta saameyn sax ah oo calaamadayn ah. Mashiinka calaamadaynta laysarka ee khadka isku-xidhka waxaa ku qalabaysan nidaam xakameyn xirfadeed iyo madaxa laysarka, kaas oo si sax ah u xarri kara qaababka calaamadaynta ama qoraalka ku yaal badeecada, taasoo hubinaysa tayada calaamadaynta.

Dabacsanaan sare: Mashiinka calaamadaynta laysarka khadka isku-dubaridka waxaa lagu hagaajin karaa oo loo habeyn karaa iyadoo loo eegayo qaabka iyo cabbirka alaabada kala duwan. Waxaa lagu qalabeeyay shaqooyin sida hagaajinta dhererka, hagaajinta booska, iyo beddelka module-ka si uu ula qabsado baahiyaha booska iyo calaamadaynta ee suufka biriiga ee kala duwan.