Umgca Wokugrumba wePosi yokuGrumba yeBrake ye-CNC

1. Isicelo:

Umgca wokuvelisa i-lining ye-brake ye-CNC u-othomathikhi opheleleyo. Usetyenziselwa ikakhulu ukucutshungulwa emva kokucinezelwa okushushu, kubandakanya ukugawula ii-arcs zangaphakathi nezangaphandle, imingxunya yokugrumba, imigca yomda wokugawula, njl.

2. Iingenelo zethu:

● Lonke umgca wemveliso uqulathe iindawo zokusebenzela ezintandathu eziphambili, zonke zilawulwa ziinkqubo ze-CNC automation. Lo mgca wemveliso unemisebenzi epheleleyo kwaye kulula ukuyisebenzisa. Zonke iiparameter zokucubungula zinokuguqulwa ngezikrini zokuchukumisa kwiqokobhe langaphandle, kwaye abasebenzi badinga kuphela ukufaka idatha yomyalelo kwikhompyutha.

● Umgca wemveliso ukwaxhotyiswe ngenkqubo yokulayisha nokukhupha izinto ngokuzenzekelayo, esusa imfuneko yokubeka iphepha ngesandla kwaye yandisa ukusebenza kakuhle kwemveliso.

● Lo mgca wemveliso ufanelekile kwizicwangciso zemveliso ezinkulu zeemodeli ngazinye, kwaye umgca wemveliso omnye unokuvelisa iziqwenga ezingama-2000 ngokusekelwe kwixesha lokusebenza leeyure ezisibhozo ngeshifti nganye.

3. Iimpawu zezikhululo zomsebenzi:

3.1 Umatshini Wokugalela Ongqukuva Wangaphandle we-Arc

3.1.1 Umzimba womatshini odibeneyo, ipleyiti yentsimbi enobukhulu obuyi-40 mm (ipleyiti ephambili yokuthwala) kunye nepleyiti yentsimbi enobukhulu obuyi-20 mm (imbambo yokuqinisa) zibekwe iintsuku ezili-15 zokusebenza emva kokudityaniswa, kwaye emva koko uxinzelelo lokudityaniswa luyasuswa ngokungcangcazela kwe-vibrator esebenza ngexesha, ngaloo ndlela yenza isakhiwo sizinze.

3.1.2 Ihabhu yevili ingatshintshwa kwimizuzu eli-15, ikhawuleza xa kutshintshwa imodeli.

3.1.3 Kuyimfuneko kuphela ukutshintsha iimold ezahlukeneyo ukuze kucutshungulwe iziqwenga zobukhulu obulinganayo nobungalinganiyo.

3.1.4 Irula yegrating yemagnethi yokubonisa yedijithali ibonelelwe ukulungiswa kwevili levili kunye nokuhamba kwevili, kunye nokuchaneka kwesibonisi se-0.005mm.

3.1.5 Ivili lokusila lisebenzisa ubuchwepheshe bedayimani obufakwe ngombane, obunomthamo omkhulu wokusila. Ububanzi bevili lokusila yi-630mm, kwaye ububanzi bomphezulu wokusila yi-50mm.

3.1.6 Ivili lokusila linesiciko esahlukileyo sokukhutshelwa kothuli, esinesiphumo sokukhutshelwa kothuli esingaphezulu kwama-90%. Umatshini uxhotyiswe ngesiciko esivalekileyo ngokupheleleyo ukuze kwahlulwe uthuli ngakumbi, kwaye kufakwe isixhobo sokukhutshelwa nokuqokelela uthuli.

3.2 Umatshini Wokugaya I-Arc Yangaphakathi

3.2.1 Lo matshini udibanisa imisebenzi emininzi yokusila ukufumana isiphelo sobuso, ukusila i-inner arc, kunye nokucoca uthuthu lwe-inner arc.

3.2.2 Ukulayisha ngokuzenzekelayo, ukubethela isilinda. Ubude nobubanzi besixhobo sokondla bunokulungiswa ngokukhawuleza. Bunokulungelelaniswa neenkcukacha ezahlukeneyo ze-brake linings ngaphandle kokutshintsha i-mold.

3.2.3 Isixhobo sokugaya esisecaleni sisebenzisa amavili amabini okugaya aqhutywa ziimoto ezikhawulezayo ukugaya omabini amacala e-brake lining ngaxeshanye, ngesantya esiphezulu somgca, ukucubungula ngokulinganayo, ukugaya okuzinzileyo, ukungcangcazela okuncinci kunye nokuchaneka okuphezulu kokucubungula. Ngexesha lokugaya, i-brake lining iyaqiniswa kwaye ibotshelelwe macala omabini ebhloko yokuma, kwaye ii-hydraulic cylinders zangaphambili nangasemva ziyabotshelelwa ukunciphisa ukufuduka kwe-brake lining kwaye zichaphazele ukuchaneka. I-hydraulic cylinder isetyenziselwa ukuqhuba i-workbench, ukuze intshukumo ihlale izinzile kwaye i-grinding grain ilingane. Sebenzisa i-electroplated diamond mushroom head grinding wheel yokugaya. Ukulungiswa kwe-grinding wheel kusebenzisa i-dovetail sliding seat, enokulungiswa phezulu nasezantsi, ngaphambili nangasemva, kunye ne-engile.

3.3 Umatshini wokutshaya i-chamfering

3.3.1 Iinkqubo ezininzi ezifana nokuxovula i-chamfering, ukucocwa komphezulu we-arc yangaphakathi kunye ne-arc yangaphandle, njl. Zingenziwa ngaxeshanye.

3.3.2 Inkqubo nganye isebenzisa isixhobo sokutsala uthuli esivaliweyo ukukhupha uthuli oluvelisiweyo, nto leyo efezekisa imveliso ecocekileyo nezenzekelayo.

3.3.3 Kwinyathelo ngalinye lokutyisa, imveliso ayizukuma kwindawo yevili lokuxukuxa kunye nevili lokuxukuxa isanti ukuze kuthintelwe ukuminxa ixesha elide kunye nokuchaphazela umgangatho wemveliso.

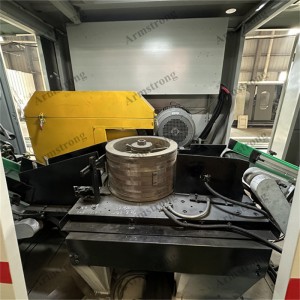

3.4 Umatshini wokugrumba

3.4.1 Ukuchaneka okuphezulu koomatshini: intambo ezi-5-10 (Umgangatho weSizwe yintambo ezi-15-30)

3.4.2 Uluhlu olubanzi lokucubungula kunye nokusebenza kakuhle okuphezulu:

Ingacubungula ii-brake pads ngobubanzi obukhulu: 225mm, R142~245mm, ububanzi bomngxuma wokubhoboza yi-10.5~23.5mm.

3.4.3 Umsebenzi omnye angasebenzisa oomatshini aba-3-4, umatshini omnye (iiyure ezi-8) ikheni ivelise iziqwenga ezili-1000-3000 zeebrake pads.

Umatshini wokuGcada oNcinci we-Arc yangaphandle oyi-3.5

3.5.1 Umzimba we-Welded sebenzisa ipleyiti yentsimbi enobukhulu obuyi-40mm (ipleyiti ephambili yokuthwala), ipleyiti yentsimbi enobukhulu obuyi-20mm (imbambo yokuqinisa), kwaye uyibeke kangangeentsuku ezili-15 zokusebenza emva kokuwelda. Emva koko, ukungcangcazela kwenziwa yi-vibrator esebenza ngexesha ukuze kupheliswe uxinzelelo lokuwelda kunye nokuzinzisa isakhiwo.

3.5.2 Ihabhu ingasuswa kwaye itshintshwe kwimizuzu eli-15.

3.5.3 Kuyimfuneko kuphela ukutshintsha iimold ezahlukeneyo ukuze kucutshungulwe iziqwenga zobukhulu obulinganayo nobungalinganiyo.

3.5.4 Ukulungiswa kwevili lokusila kunye nokuhamba kwehabhu yevili kuxhotyiswe ngerula yegridi yemagnethi yokubonisa yedijithali, echanekileyo yokubonisa ye-0.005mm.

3.5.5 Ivili lokusila lisebenzisa ubuchwepheshe bedayimani obufakwe ngombane, obunemigca emincinci yokusila kunye nobubanzi obuyi-630 mm. Ivili lokusila elijikelezayo libonelelwa ukusila kakuhle i-arc yangaphandle, ukuqinisekisa ukuba imigca yokusila yangaphandle iyafana ne-arc yangaphakathi.

3.6 Umatshini Wokugawula Umgca Olinganiselweyo

3.6.1 Le modeli isebenzisa ubuchwepheshe beentloko ezininzi zokusila, ezinokusila ngaxeshanye imilinganiselo esecaleni kunye nomgca womda we-brake lining, kwaye zingakhetha ukucubungula enye yazo.

3.6.2 Isilinda somoya sityhala i-brake lining kwi-module ngexesha lokulayisha. Kukho izixhobo zokhokelo lwe-pneumatic kunye nezixhobo zokubeka indawo kumacala omabini e-hub ukwenza i-brake linings inamathele kwi-module ngaphandle kokutshintsha okuqhelekileyo.

3.6.3 Ivili lokusila lisebenzisa ivili lokusila ledayimani elifakwe ngombane.

3.6.4 Ivili lokusila licubungula ububanzi okanye umda we-brake lining ngaxeshanye.

3.6.5 Hlanganisa iimodyuli kwihabhu yamavili, kwaye utshintshe uhlobo lwemveliso. Ziimodyuli ezihambelanayo kuphela ekufuneka zitshintshwe.

3.6.6 Ivili lokusila liqiniswe ngesilayidi esinqamlezileyo sedovetail, esinokulungiswa size sihanjiswe kumacala amabini. Uhlengahlengiso ngalunye lwecala luxhotyiswe nge-digital display positioner enokuchaneka kokubonisa kwe-0.01 mm.

3.6.7 Inxalenye yamandla kunye nendawo yokuxhasa zifakwe ipleyiti yentsimbi enobukhulu obuyi-30mm. Yongeza isiciko esivalekileyo ngokupheleleyo kwisixhobo ukuze ukwahlukanise uthuli ngakumbi, kwaye ufake isixhobo sokufunxa nokuqokelela uthuli.