Umugqa Wokugaya Weposi Yokubopha I-CNC Brake Lining

1. Isicelo:

Umugqa wokukhiqiza ulwelwesi lwamabhuleki we-CNC uzenzakalelayo ngokuphelele futhi usetshenziselwa kakhulu ukucutshungulwa ngemuva kokufakwa kolwelwesi lwamabhuleki ngemuva kokucindezela okushisayo, okuhlanganisa ukugaya ama-arcs angaphakathi nangaphandle, imigodi yokubhoboza, imigqa yomkhawulo wokugaya, njll.

2. Izinzuzo Zethu:

● Lonke umugqa wokukhiqiza uqukethe izindawo zokusebenza eziyisithupha eziyinhloko, zonke ezilawulwa izinhlelo ze-CNC ezenzakalelayo. Lo mugqa wokukhiqiza unemisebenzi ephelele futhi kulula ukuwusebenzisa. Zonke izinhlaka zokucubungula zingashintshwa ngezikrini zokuthinta egobolondweni langaphandle, futhi abasebenzi badinga kuphela ukufaka idatha yomyalo kukhompyutha.

● Umugqa wokukhiqiza uphinde ufakwe uhlelo lokulayisha nokulayisha ngokuzenzakalelayo, oluqeda isidingo sokubekwa kweshidi ngesandla futhi lukhulise ukusebenza kahle kokukhiqiza.

● Lo mugqa wokukhiqiza ufanelekela izinhlelo zokukhiqiza ezinkulu zamamodeli ngamanye, futhi umugqa wokukhiqiza owodwa ungakhiqiza izingcezu ezingu-2000 ngokusekelwe esikhathini sokusebenza samahora ayisishiyagalombili ngeshifti ngayinye.

3. Izici zeziteshi zomsebenzi:

3.1 Umshini Wokugaya Oqinile We-Arc Yangaphandle

3.1.1 Umzimba womshini oshiselwe, ipuleti lensimbi elingu-40 mm ubukhulu (ipuleti lokuthwala eliyinhloko) kanye nepuleti lensimbi elingu-20 mm ubukhulu (ubambo lokuqinisa) zibekwa izinsuku ezingu-15 zokusebenza ngemva kokushisela, bese ukucindezeleka kokushisela kususwa ngokudlidliza kwesidlidlizi esisebenza kahle ngesikhathi, ngaleyo ndlela senza isakhiwo siqine.

3.1.2 Ihabhu yesondo ingashintshwa ngemizuzu eyi-15, iyashesha ukushintsha imodeli.

3.1.3 Kudingeka kuphela ukushintsha izikhunta ezahlukene ukuze kucutshungulwe izingcezu zobukhulu obulinganayo nobungalingani.

3.1.4 Irula le-grating elibonisa idijithali linikezwa ukulungiswa kwesondo lesondo kanye nokuhamba kwesondo, ngokunemba kwesibonisi okungu-0.005mm.

3.1.5 Isondo lokugaya lisebenzisa ubuchwepheshe bedayimane obufakwe ngogesi, obunomthamo omkhulu wokugaya. Ububanzi besondo lokugaya bungu-630mm, kanti ububanzi bendawo yokugaya bungu-50mm.

3.1.6 Isondo lokugaya linesembozo esihlukile sokukhipha uthuli, esinomphumela wokukhipha uthuli ongaphezu kuka-90%. Umshini ufakwe indawo evalekile ngokuphelele ukuze uhlukanise uthuli, futhi kufakwa idivayisi yokukhipha nokuqoqa uthuli.

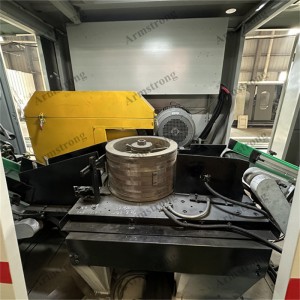

3.2 Umshini Wokugaya I-Arc Yangaphakathi

3.2.1 Lo mshini uhlanganisa imisebenzi eminingi yokugaya ukuthola ubuso bokugcina, ukugaya i-arc yangaphakathi, kanye nokuhlanza umlotha wangaphakathi we-arc.

3.2.2 Ukulayisha okuzenzakalelayo, ukubopha ngesilinda. Ubude nobubanzi bedivayisi yokondla kungalungiswa ngokushesha. Ingazivumelanisa nezincazelo ezahlukene zama-lining amabhuleki ngaphandle kokushintsha isikhunta.

3.2.3 Idivayisi yokugaya emaphethelweni isebenzisa amasondo amabili okugaya aqhutshwa yizinjini ezisheshayo ukugaya zombili izinhlangothi zomugqa wamabhuleki ngesikhathi esisodwa, ngesivinini esiphezulu esiqondile, ukucubungula okulinganayo, ukugaya okuzinzile, ukudlidliza okuncane kanye nokunemba okuphezulu kokucubungula. Ngesikhathi sokugaya, umugqa wamabhuleki uyaqiniswa futhi uboshwe yizinhlangothi zombili zebhulokhi yokuma, futhi amasilinda e-hydraulic angaphambili nangemuva ayaboshwa ukuze kuncishiswe ukufuduka komugqa wamabhuleki futhi kuthinte ukunemba. Isilinda se-hydraulic sisetshenziselwa ukushayela ibhentshi lokusebenzela, ukuze ukunyakaza kuzinzile futhi uhlamvu lokugaya lulingane. Sebenzisa isondo lokugaya ikhanda lama-mushroom elifakwe ngogesi ukuze ligaywe. Ukulungiswa kwesondo lokugaya kusebenzisa isihlalo esishelelayo se-dovetail, esingalungiswa phezulu naphansi, ngaphambili nangemuva, kanye ne-engeli.

3.3 Umshini Wokuxova Ama-Chamfering

3.3.1 Izinqubo eziningi ezifana nokuhlikihla i-chamfering, ukuhlanza ubuso be-arc yangaphakathi kanye ne-arc yangaphandle, njll. Kungenziwa ngesikhathi esisodwa.

3.3.2 Inqubo ngayinye isebenzisa idivayisi yokukhipha uthuli evaliwe ukukhipha uthuli olukhiqizwe, okufeza ukukhiqizwa okuhlanzekile nokuzenzakalelayo.

3.3.3 Esinyathelweni ngasinye sokudla, umkhiqizo ngeke ume endaweni yesondo lokuxubha kanye nesondo lokuxubha isihlabathi ukuze kugwenywe ukuqina kwesikhathi eside futhi kuthinte ikhwalithi yomkhiqizo.

3.4 Umshini Wokubhoboza

3.4.1 Ukunemba okuphezulu komshini: intambo engu-5-10 (Indinganiso kazwelonke inguntambo engu-15-30)

3.4.2 Ububanzi bokucubungula kanye nokusebenza kahle okuphezulu:

Ingacubungula ama-brake pad ngobubanzi obukhulu: 225mm, R142~245mm, ububanzi bomgodi wokubhoboza bungu-10.5~23.5mm.

3.4.3 Isisebenzi esisodwa singasebenzisa imishini emi-3-4, umshini owodwa (amahora ayi-8) ikani ukukhiqiza izingcezu zama-brake pad eziyi-1000-3000.

Umshini Wokugaya Ocwebezelayo Wangaphandle ongu-3.5

3.5.1 Umzimba oshiselwe usebenzisa ipuleti lensimbi elingu-40mm ubukhulu (ipuleti lokuthwala eliyinhloko), ipuleti lensimbi elingu-20mm ubukhulu (ubambo lokuqinisa), bese ulibeka izinsuku ezingu-15 zokusebenza ngemva kokushisela. Ngemuva kwalokho, ukudlidliza kwenziwa nge-vibrator esebenza kahle ngesikhathi ukuze kuqedwe ukucindezeleka kokushisela futhi kuqiniswe isakhiwo.

3.5.2 Ihabhu lingasuswa futhi lifakwe elinye zingakapheli imizuzu eyi-15.

3.5.3 Kudingeka kuphela ukushintsha izikhunta ezahlukene ukuze kucutshungulwe izingcezu zobukhulu obulinganayo nobungalingani.

3.5.4 Ukulungiswa kwesondo lokugaya kanye nokunyakaza kwehabhu lamasondo kufakwe irula legridi yamagnetic yokubonisa yedijithali, enokunemba kokubonisa okungu-0.005mm.

3.5.5 Isondo lokugaya lisebenzisa ubuchwepheshe bedayimane obufakwe ngogesi, obunemigqa yokugaya emincane kanye nobubanzi obungu-630 mm. Kunikezwa isondo lokugaya eligoqekayo ukuze ligaye kahle i-arc yangaphandle, ukuqinisekisa ukuthi imigqa yokugaya ye-arc yangaphandle ifana ne-arc yangaphakathi.

3.6 Umshini Wokugaya Umugqa Olinganiselwe

3.6.1 Lo modeli usebenzisa ubuchwepheshe bekhanda lokugaya obuningi, obungagaya ubukhulu obuseceleni kanye nomugqa okhawulelwe we-brake lining ngasikhathi sinye, futhi bungakhetha ukucubungula eyodwa yazo.

3.6.2 Isilinda somoya sisunduza ulwelwesi lwamabhuleki kumojuli ngesikhathi sokulayisha. Kuneziqondiso zomoya kanye namadivayisi okubeka izintambo zombili zehabhu ukwenza ulwelwesi lwamabhuleki lunamathele kumojuli ngaphandle kokushintshashintsha okuhlobene.

3.6.3 Isondo lokugaya lisebenzisa isondo lokugaya idayimane elifakwe ngogesi.

3.6.4 Isondo lokugaya licubungula ububanzi noma umkhawulo we-brake lining ngasikhathi sinye.

3.6.5 Hlanganisa amamojula kuhabhu lamasondo, bese ushintsha uhlobo lomkhiqizo. Amamojula ahambisanayo kuphela okudingeka ashintshwe.

3.6.6 Isondo lokugaya liqiniswe ngesilayida esinqamula umsila wedovetail, esingalungiswa futhi sihanjiswe ngezindlela ezimbili. Ukulungiswa ngakunye kokuqondisa kufakwe i-digital display positioner enokunemba kokubonisa okungu-0.01 mm.

3.6.7 Ingxenye yamandla kanye nendawo yokusekela kuhlanganiswe ngepuleti lensimbi elingu-30mm ubukhulu. Faka indawo evalekile ngokuphelele emishinini ukuze uhlukanise uthuli, bese ufaka idivayisi yokumunca nokuqoqa uthuli.