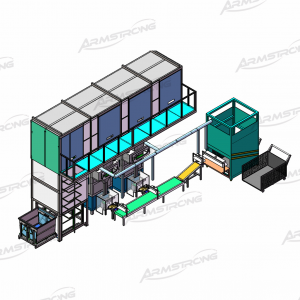

Umugqa Wokukala Izinto Nokupakisha Okungaphansi

1. Isicelo:

Kala izinto zokungqubuzana eziqinile bese upakisha izinto ezingavuthiwe ezikhwameni zepulasitiki, ukuze izikhwama ngasinye zifakwe ngqo emgodini wesikhunta ukuze zicindezelwe, okunciphisa kakhulu uthuli enqubweni yokucindezela.

Umshini wokukala nowokuphakela we-CNC ulula ukusebenza, uphephile kakhulu, futhi ufanelekela ukufaka esikhundleni somsebenzi wezandla. Lo mshini unamandla amakhulu okuhamba futhi ungathuthukisa kakhulu ukusebenza kahle kokukhiqiza, ngeke ubhajwe ukunganaki kwabantu noma ukuntuleka kwabasebenzi. Ngenxa yokusebenzisa ukulawula isikrini sokuthinta kanye nohlelo oluzenzakalelayo oluqhutshwa yi-servo motor, unezinzuzo zokondla okungayeki, ukunemba kwesisindo okuphezulu, futhi ungenza ngokuzenzakalelayo umugqa wokukhiqiza. Uyithuluzi elibukhali lokuthuthukisa ukukhiqizwa kwendwangu yamabhuleki endabuko.

2. Ukwakheka Komugqa:

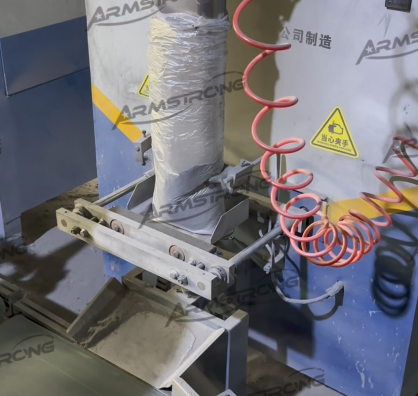

2.1Umshini wokwenza izikhwama ozenzakalelayo

Mfaka izikhwama ngokuzenzakalelayo bese uslayida izikhwama zepulasitiki ezisetshenziselwa ukufaka esikhwameni epayipini lokudla ngedivayisi yomshini.

Umshini ngamunye osebenza ungenza izikhwama ezingaba ngu-170, kanti umshini owodwa wokwenza izikhwama ungahlangabezana nezidingo zokufaka izikhwama zamasethi ayi-8 emishini yokukala nokufaka izikhwama.

Umshini wokwenza izikhwama usebenzisa ukulawula kwe-PLC, okungasetha ububanzi besikhwama kanye nemingcele yesivinini sokufaka izikhwama.

Isikhafu sefilimu yepulasitiki

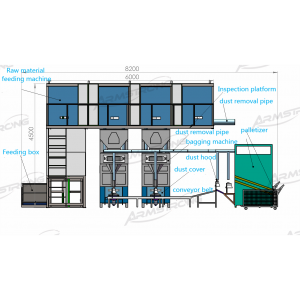

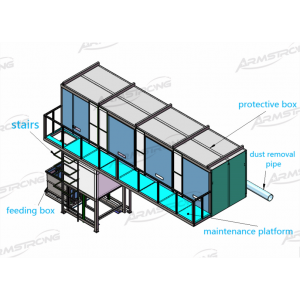

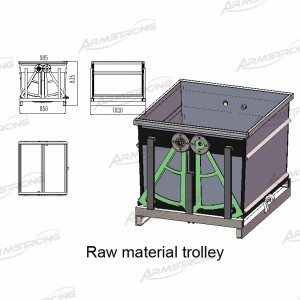

2.2Umshini wokondla izinto ezingavuthiwe

Isebenzisa imoto ekhethekile yokugcina engu-400Kg, isebenzisa ilifti yentambo ukuphakamisa ibhokisi lokudla liye endaweni efanele, bese idlula ngendlela evundlile idlule emzileni iye emnyango oqokiwe womshini wokulinganisa nokufaka izikhwama. Bese ikhipha izinto ezisele emngxunyeni ongaphansi kwebhokisi lokudla elizivulekelayo.

Yonke inqubo isebenzisa isakhiwo esivaliwe, kanye nezinyathelo zokukhipha uthuli eziqinile, ezingahlangabezana nezidingo zokuvikela imvelo. Isebenzisa ukulawulwa kwe-PLC futhi ilinganise ibhokisi lokudla le-lifti online nganoma yisiphi isikhathi ukuqinisekisa ukuphepha nokuthembeka ngesikhathi senqubo yokuphakamisa.

Umshini owodwa wokondla ungalinganiswa nemishini emithathu yokukala nokufaka izikhwama.

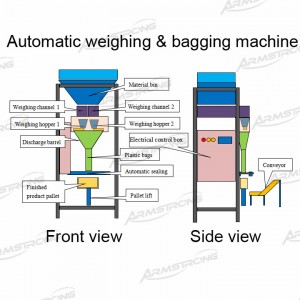

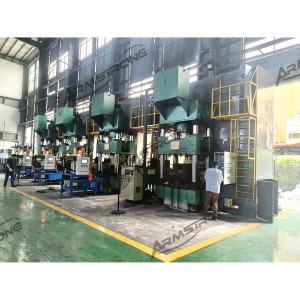

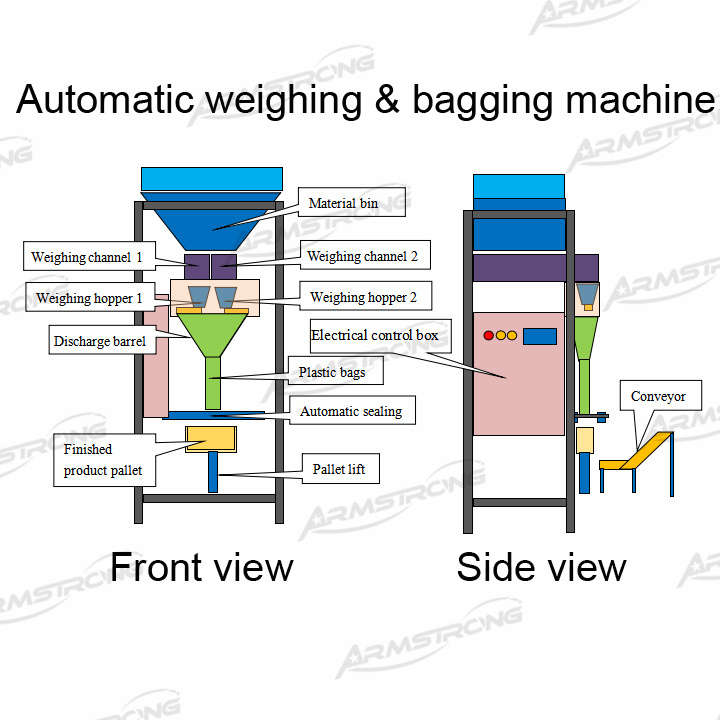

2.3Umshini wokulinganisa nokufaka izikhwama ozenzakalelayo

Umshini wokulinganisa nokufaka izikhwama ozenzakalelayo wakhiwe ngesakhiwo sokulinganisa okuzenzakalelayo, ukulinganisa nokunikeza izinto zokusetshenziswa okuzenzakalelayo, ukulawula kwedijithali kwesikrini sokuthinta, kanye neyunithi ye-servo yokudla yekheji elikabili, kanye nengxenye yokulinganisa yesiteshi esikabili.

Umshini wokukala nowokuphakela we-CNC ulula ukusebenza, uphephile kakhulu, futhi ufanelekela ukufaka esikhundleni somsebenzi wezandla. Lo mshini unamandla amakhulu okuhamba futhi ungathuthukisa kakhulu ukusebenza kahle kokukhiqiza, ngeke ubhajwe ukunganaki kwabantu noma ukuntuleka kwabasebenzi. Ngenxa yokusebenzisa ukulawula isikrini sokuthinta kanye nohlelo oluzenzakalelayo oluqhutshwa yi-servo motor, unezinzuzo zokondla okungayeki, ukunemba kwesisindo okuphezulu, futhi ungenza ngokuzenzakalelayo umugqa wokukhiqiza. Uyithuluzi elibukhali lokuthuthukisa ukukhiqizwa kwendwangu yamabhuleki endabuko.

Isivinini ngasinye sokufaka izikhwama zomshini:≤3.2 isikhwama/umzuzu (1250g)

Ibanga lokulinganisa ngesikhwama ngasinye: 900 ~ 2400g

2.4I-Palletizer Ezenzakalelayo

Ukuze sinciphise amandla abasebenzi, siklame futhi sakhiqiza amasethi amaningi emishini yokulinganisa nokufaka izikhwama ye-CNC ezenzakalelayo ukuze ithuthe ngokuzenzakalelayo izinto ezifakwe emasakeni ziye emnyango we-palletizer ngebhande lokuhambisa, futhi simise amapharamitha afanele ngokuya ngesofthiwe ekhethekile kanye nencwadi yesandla ngokutholwa okuzenzakalelayo kwemishini, amarobhothi okukhipha ugesi, ukucindezela kanye ne-truss.

Qedela iqembu lezikhwama ezingaba ngu-5, ezifakwe kahle elolini lokugcina impahla elikhethekile eliqokiwe (noma ebhokisini lenkampani yakho lokushintshana). Inani lezendlalelo zokufaka ama-pallet lingabekwa (≤ izendlalelo ezingu-12), bese kuthi i-alamu ezenzakalelayo isho ukuthini lapho ukufakwa kwama-pallet kuqediwe.

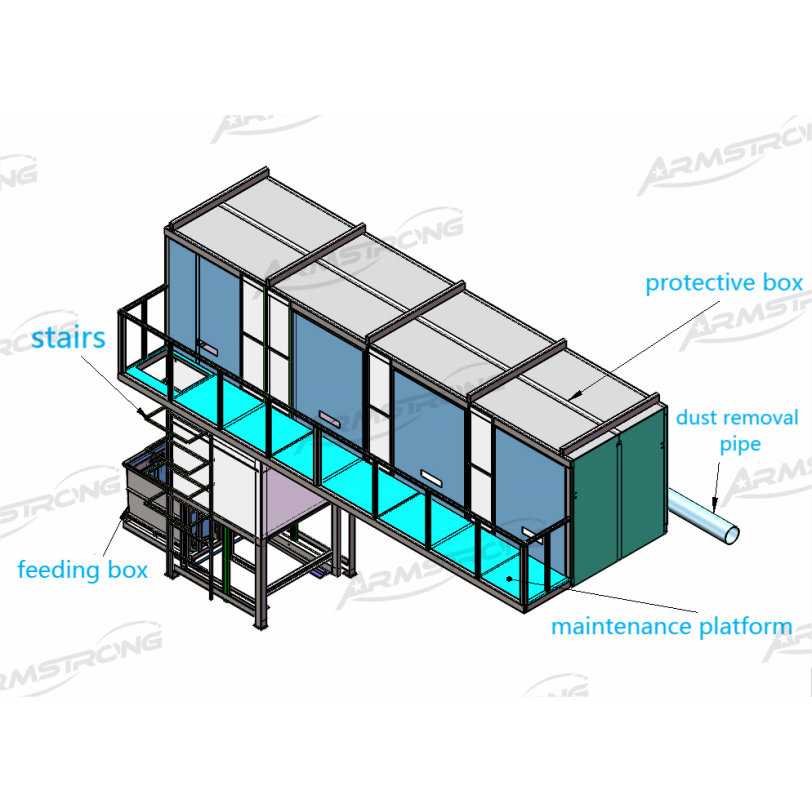

2.5Uhlelo lwamapayipi okususa nokuvimbela uthuli

Umugqa ngamunye usethelwe uhlelo lokususa uthuli ukuze kuncishiswe uthuli lokungqubuzana ngesikhathi sokudla nokulinganisa, senza konke okusemandleni ethu ukunciphisa uthuli endaweni yokusebenzela futhi sivikele isisebenzi'impilo yomzimba.