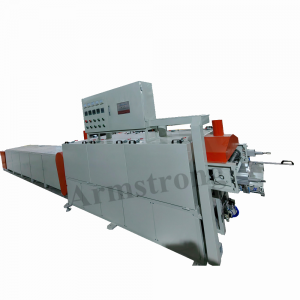

1200L plow thiab rake mixing tshuab

1. Daim ntawv thov:

RP870 1200L plow thiab rake tov khoom yog dav siv nyob rau hauv kev sib txhuam cov ntaub ntawv, steel, feed processing thiab lwm yam teb ntawm raw cov ntaub ntawv sib tov.

Cov khoom siv feem ntau yog tsim los ntawm cov khib nyiab, kev kub ceev stirring cutter, spindle system thiab lub thoob lub cev.Zoo ib yam li RP868 800L tov khoom, RP870 yog qhov loj dua hauv kev ntim ntim.Yog li nws tsim nyog rau cov kws tshaj lij nres nres ua lub Hoobkas nrog cov khoom xav tau loj.

2.Txoj cai ua haujlwm

Nyob rau hauv nruab nrab ntawm kab rov tav axis ntawm lub thoob lub thoob, muaj ntau yam plough-zoo li tus sib tov shovels tsim los tig kom cov khoom txav nyob rau hauv tag nrho qhov chaw ntawm lub thoob.Ib sab ntawm lub chim yog nruab nrog ib tug high-speed stirring riam. , uas yog siv los txhim kho kev sib xyaw ua kom zoo dua qub thiab txhawm rau txhawm rau cov pob hauv cov khoom kom ntseeg tau tias cov hmoov, kua thiab slurry additives yog sib xyaw kom zoo.Integrating mixing and crushing mechanism is the biggest advantage of the plow - rake mixer.

3. Peb qhov zoo:

1. Nruam pub noj thiab tawm, siab sib xyaw

Cov qauv ntawm lub tov khoom yog tsim los nrog ib tug ncej thiab ntau rake hniav, thiab cov hniav rake yog teem nyob rau hauv sib txawv geometric duab, thiaj li hais tias cov ntaub ntawv yog muab pov rau hauv ib tug rov qab thiab tawm mus rau hauv cov ntaub ntawv nyob rau hauv tag nrho lub cev ntawm lub tov khoom, thiaj li. kom paub txog kev sib xyaw ntawm cov khoom.

Lub tshuab tov khoom no tshwj xeeb tshaj yog tsim rau kev sib xyaw cov hmoov thiab hmoov, thiab tseem tuaj yeem siv rau kev sib xyaw ntawm cov hmoov thiab cov kua me me (binder), los yog sib tov ntawm cov khoom uas muaj qhov sib txawv loj loj.

2. Cov khoom siv ua haujlwm ruaj khov

Lub tov khoom muaj cov qauv kab rov tav.Cov ntaub ntawv uas yuav tsum tau tov yog input rau hauv lub tov khoom los ntawm txoj siv thiab sib tov los ntawm cov khoom sib tov.Lub thoob ntawm lub tov khoom yog nruab nrog roj hmab hauv ob sab phlu, thiab tsis txhob cia nws lo.Cov cuab yeej sib xyaw yog ua los ntawm cov hlau hnyav hnav-tiv taus thiab welded nrog hnav-resistant vuam pas nrig nrog lub neej ua haujlwm ntev.Lub tshuab tov khoom tau siv ntau lub teb rau ntau xyoo, thiab kev xyaum tau ua pov thawj tias nws cov qauv tsim tsim nyog, nws txoj haujlwm ruaj khov, thiab nws cov kev saib xyuas yooj yim.

3. Muaj zog sealing kev ua tau zoo thiab me ntsis cuam tshuam rau ib puag ncig

Kab rov tav plow tov khoom yog kab rov tav kaw yooj yim qauv, thiab qhov nkag thiab qhov hluav taws xob yooj yim txuas nrog cov khoom siv tshem tawm plua plav, uas tsis tshua muaj kev cuam tshuam rau ib puag ncig ntawm thaj chaw sib xyaw.

Tshem tawm hom kab rov tav plow tov khoom: cov khoom siv hmoov siv pneumatic loj qhib qauv, uas muaj qhov zoo ntawm kev tawm sai thiab tsis muaj qhov seem.