Auto Hot Pressing Line

1. Application:

Hot pressing is the most important process of the brake lining production. While during material feeding & pressing, the working area is always dusty. All workers need to wear protective mask during production.

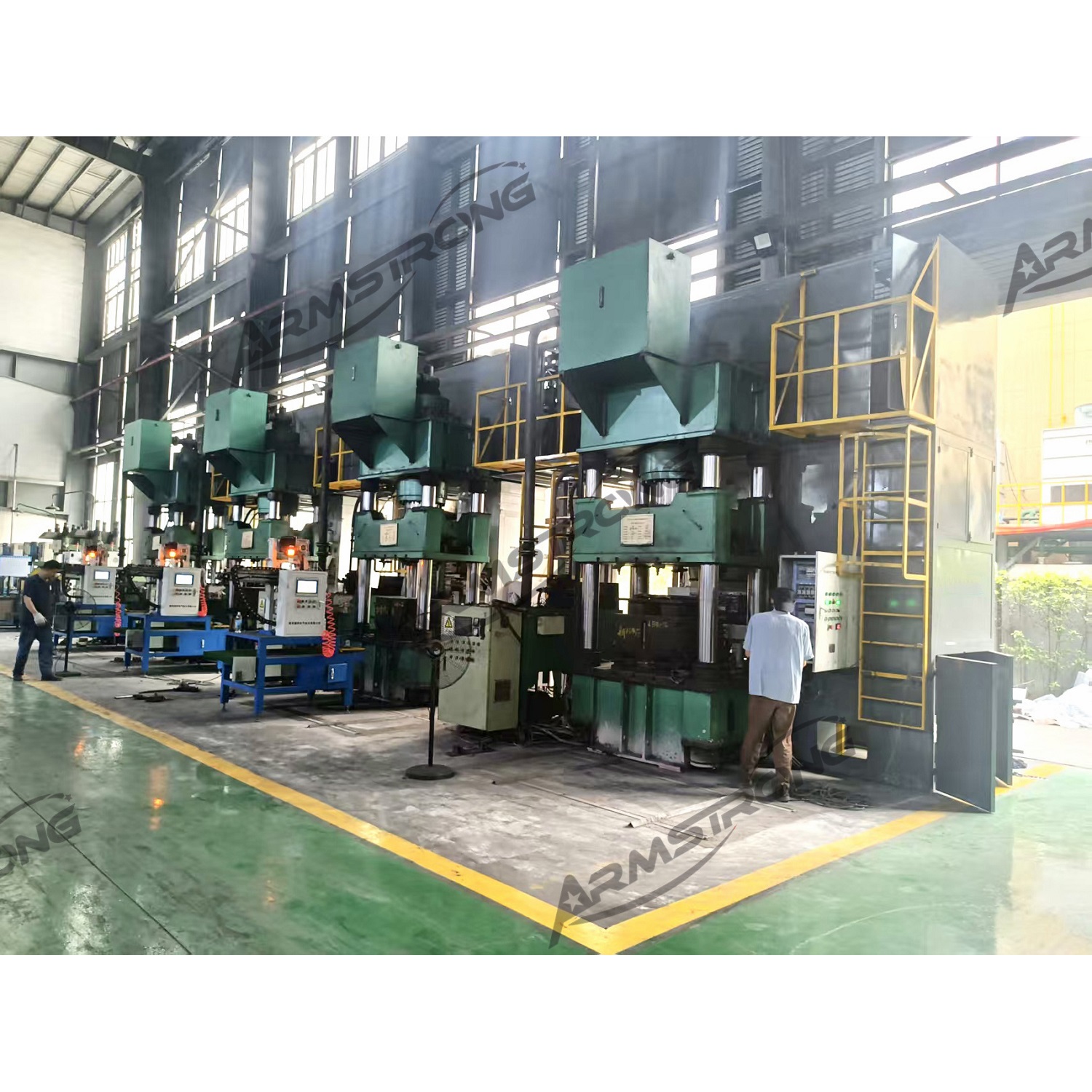

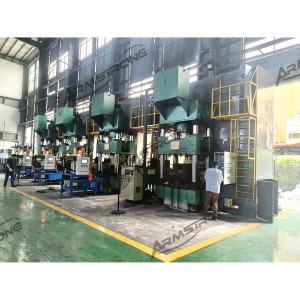

In order to improve production efficiency and reduce labor costs, we develop the auto pressing line for brake lining. In the past, one worker was in charge of one or two press machines, but now one worker can be in charge of one hot pressing automatic line ( four hot press machines).

2. Line Composition:

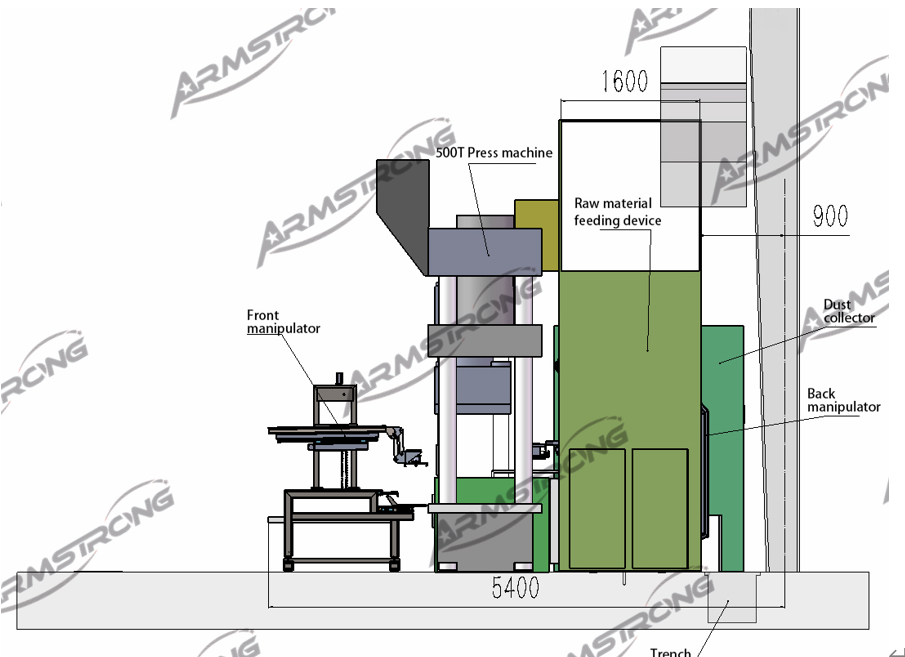

2.1 Raw material trolley feeding device

The mixing machine each cycle can mix around 250kg raw material . In order to adapt with this mixing capacity, we especially design the automatic feeding device with a loading capacity of 250kg.

The automatic trolley feeding device adopts a dedicated trolley with a storage capacity of 250Kg (0.4m ³), and uses a steel wire rope (4 ropes 10mm) type elevator to lift the dedicated feeding trolley to the appropriate position and then proceed in the designated horizontal direction. Move to the entrance of the feeding trolley on the two channel weighing machine through the track, and then automatically unload the raw material from the trolley bottom.

One set of material feeding device can connect with Max. 4 unit of hot pressing machines. In addition, this four hot press machine can produce 4 different formulas at same time.

Raw Material Feeding Trolley

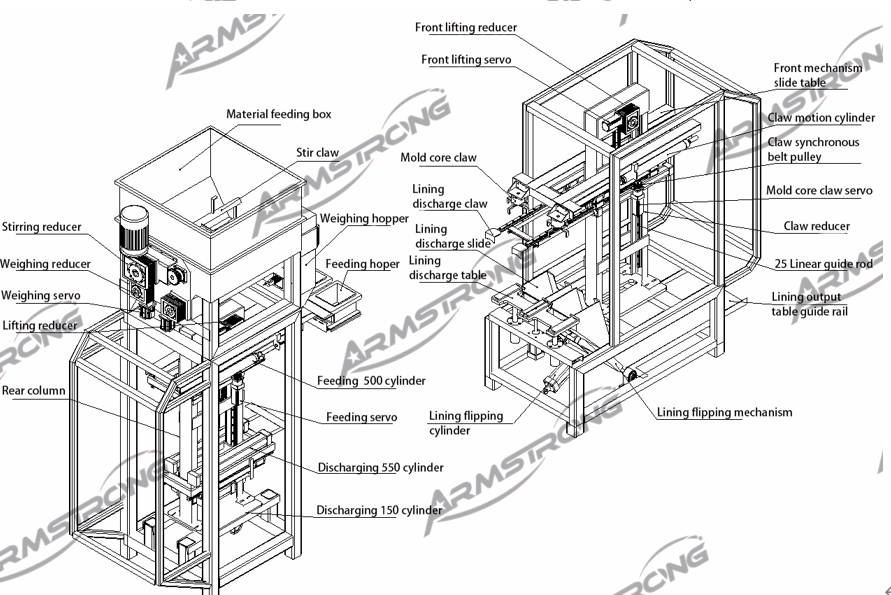

1.1 Auto weighing, feeding & discharging device

This device mainly has following functions:

1.1.1 Weigh the request raw material grams

1.1.2 Feed the raw material into mold cavity & leveling the material in cavity

1.1.3 Spray the release agent on mold core

1.1.4 Place the mold core in mold

1.1.5 Discharge the finished brake lining from press machine to worktable

The auto device cycling work for each layer pressing, worker no need to manual spray release agent or pour raw material into mold. One press machine equip with one set of Auto weighing, feeding & discharging device.

2.3 Hot press machine

Hot press machine suggest to use 500Ton or 630T for brake lining. The mold is normally designed as 8 layers 4 cavities type.

3. Our Advantages

3.1 Significantly improving production efficiency: Automated hot pressing lines can achieve continuous production, significantly increasing output compared to traditional single machine or semi automated production methods. The data shows that one press machine per shift output has increased from the traditional 600 pieces to around 1000 pieces after automation.

3.2 Reduce manpower demand: In traditional semi-automatic mode, one person can only operate 1 or 2 presses, while in fully automatic hot pressing lines, one person can operate 1-2 auto line (4-8 presses), greatly reducing labor costs.

3.3 Improving product quality: Automated equipment ensures precise control of each pressing time and pressure, weighing devices ensure accurate raw material ratios, reduce human operational errors, and improve product consistency and stability.

3.4 Improving the working environment: Under traditional production modes, workers need to work in high temperature and high dust environments. Automated production lines reduce direct exposure to harmful environments and protect workers' health.

3.5 Improve accuracy: Compared to manual loading of partitions, automated equipment can ensure precise control of the gap between partitions and mold cavities, improve the forming accuracy of drum brake pads, and reduce subsequent processing volume.

3.6 Reduce comprehensive production costs - Although equipment investment is significant, in the long run, the production cost of each brake pad can be significantly reduced by improving production efficiency, reducing labor, lowering energy consumption, and increasing raw material utilization.