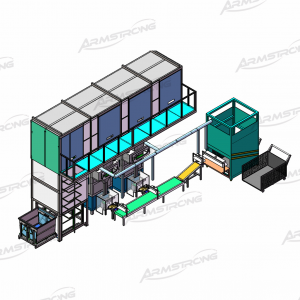

Material Weighing & Sub-Packing Line

1.Application:

Weigh the settled friction material and pack the raw material in plastic bags, so that each bags directly put in mold cavity for pressing, which greatly reduce the dust in pressing process.

The CNC weighing and feeding machine has simple operation, high safety, and is suitable for replacing manual labor. This equipment has high maneuverability and can greatly improve production efficiency, it will not stuck by human negligence or lack of personnel. Due to the use of touch screen control and servo motor driven automatic system, it has the advantages of non-stop feeding, high weighing accuracy, and can fully automate the production line. It is a sharp tool for improving traditional manual brake lining production.

2.Line Composition:

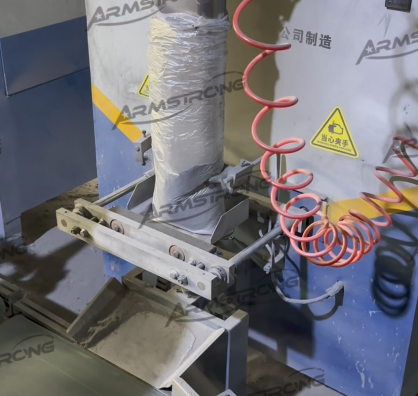

2.1 Automatic bag making machine

Make bags automatically and slide the plastic bags used for bagging onto the feeding tube through mechanical device.

Each machine running can make about 170 bags, and one bag making machine can meet the bagging requirements of 8 sets of weighing & bagging machines.

The bag making machine adopts PLC control, which can set the bag width and bagging speed parameters.

Plastic film sleeve

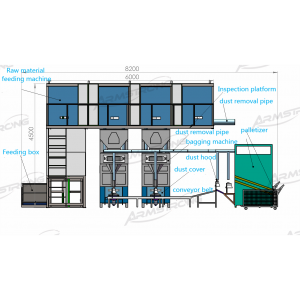

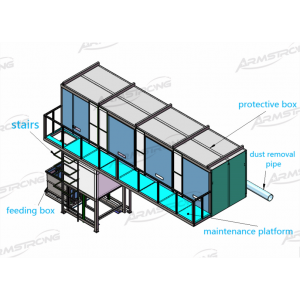

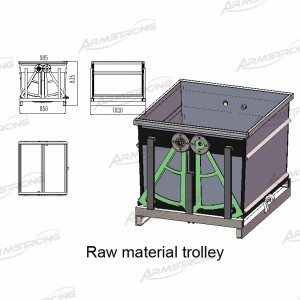

2.2 Raw material feeding machine

It adopts the special vehicle of 400Kg storage, uses the wire rope elevator to lift the feeding box to the appropriate position, and then moved horizontally through the track to the designated entrance of the weighing & bagging machine. Then discharge the material from the opening at the bottom of the self-opening feeding box.

The whole process adopts closed structure, plus quipped strong dust extraction measures, which could meet environmental protection requirements. It adopts PLC control and scales the feeding box of the elevator online at any time to ensure safety and reliability during the lifting process.

One feeding machine can be matched with three weighing & bagging machines.

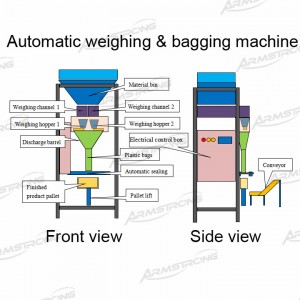

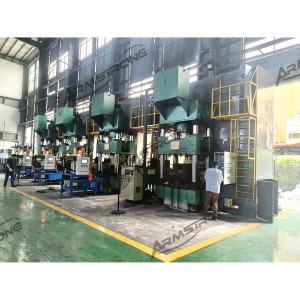

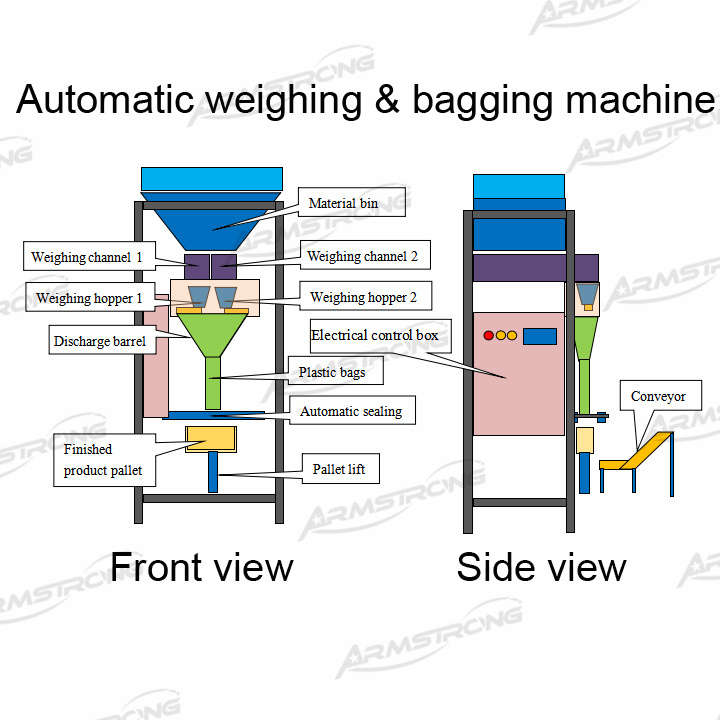

2.3Automatic weighing & bagging machine

The automatic weighing & bagging machine is composed of an automatic weighing structure, automatic weighing and feeding of raw materials, touch screen digital control, and a dual cage feeding servo unit, as well as a dual channel weighing part.

The CNC weighing and feeding machine has simple operation, high safety, and is suitable for replacing manual labor. This equipment has high maneuverability and can greatly improve production efficiency, it will not stuck by human negligence or lack of personnel. Due to the use of touch screen control and servo motor driven automatic system, it has the advantages of non-stop feeding, high weighing accuracy, and can fully automate the production line. It is a sharp tool for improving traditional manual brake lining production.

Each machine bagging speed: ≤3.2bag/min (1250g)

Weighing range per bag: 900~2400g

2.4 Automatic Palletizer

In order to reduce the labor intensity of workers, we has designed and produced multiple sets of CNC automatic weighing & bagging machines to automatically transport the bagged material to the entrance of the palletizer through the conveyor belt, and set relevant parameters according to the special software and manual through the automatic detection of equipment, exhaust, pressing and truss robots.

Complete a group of about 5 bags, neatly palletized to the designated special storage truck (or your company's turnover box). The number of layers of palletizing can be set (≤12 layers), and the automatic alarm prompts when palletizing is completed.

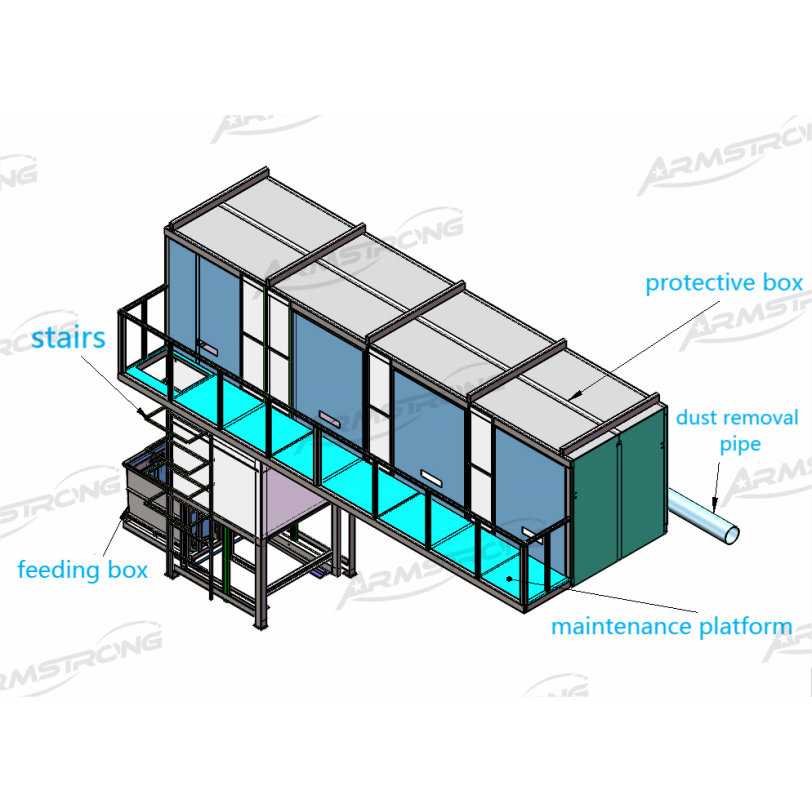

2.5Dust removal & prevention pipeline system

Each set line equip with dust removal system to reduce the friction dust during feeding & weighing, do our best to reduce the dust in the workshop and protect worker’s physical health.