——How Armstrong Empowered MK Kashiyama Brake Production in 2025

MK Kashiyama is a distinguished and technologically advanced manufacturer in Japan’s automotive components sector, renowned for its high-performance brake pads that prioritize safety, durability, and precision engineering. With a strong reputation built on rigorous quality standards and continuous innovation, MK Kashiyama serves a global clientele, including leading automotive manufacturers and aftermarkets. Their commitment to excellence in both product development and manufacturing processes makes them a trusted name in the industry.

[Hangzhou, 2025-3-10] – Armstrong, a globally recognized provider of high-precision industrial testing and manufacturing equipment, is proud to announce a successful partnership with MK, a premier and highly respected brake pad manufacturer based in Japan.

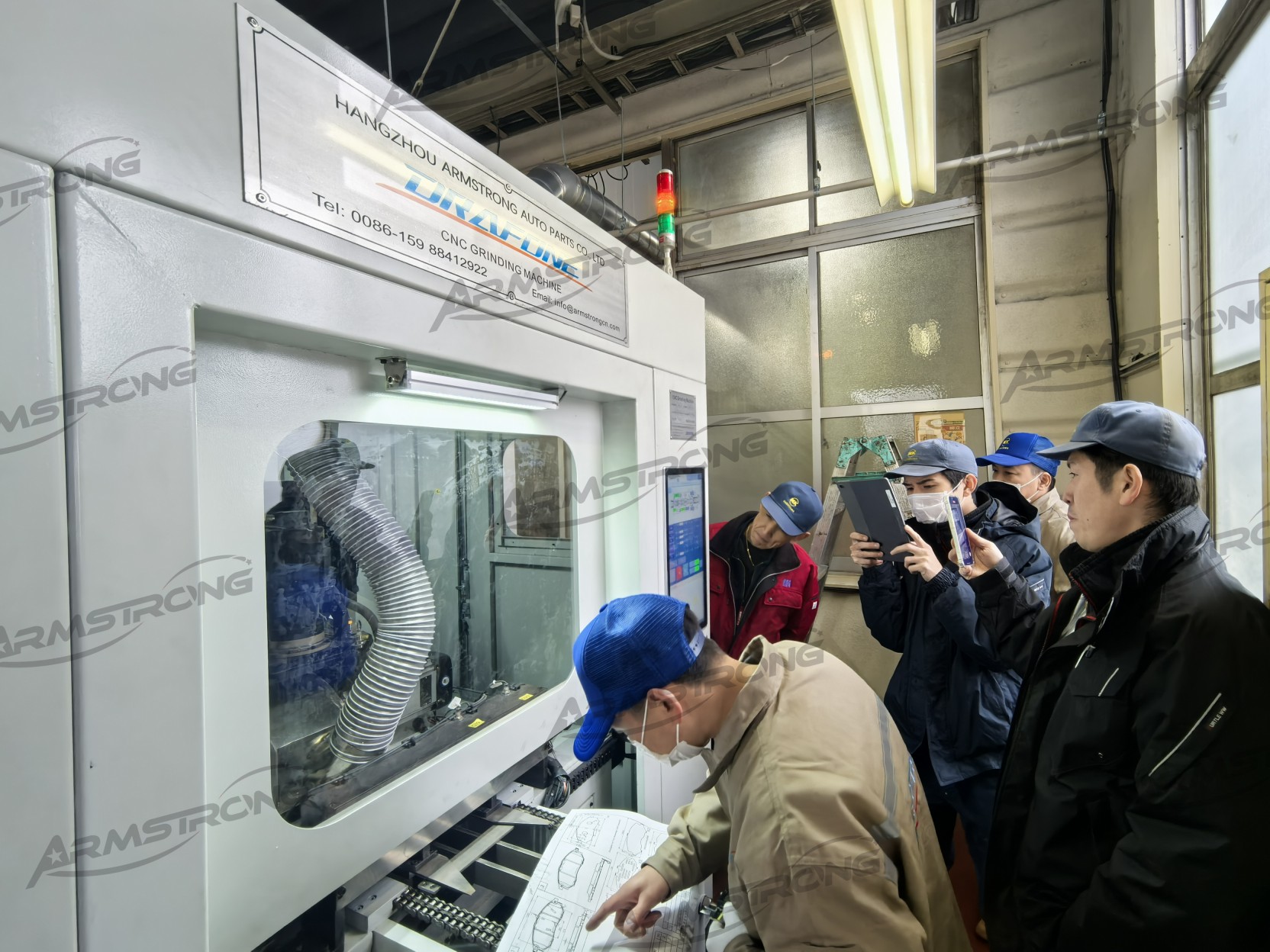

In a significant development in 2025, a delegation from MK visited Armstrong’s production facility. The visit underscored MK’s commitment to enhancing its manufacturing capabilities with world-class technology. During the comprehensive tour, MK’s experts closely examined Armstrong’s advanced workshops and witnessed detailed equipment demonstrations, gaining firsthand insight into the robustness, precision, and innovation embedded in Armstrong’s solutions.

MK engineers inspecting the processed back plates

Following productive and friendly discussions, both parties solidified a collaborative agreement. MK confirmed the procurement of a batch of specialized equipment from Armstrong, tailored to meet their stringent quality and production requirements.

Demonstrating exceptional commitment and operational efficiency, the Armstrong engineering team completed the manufacturing of the designated equipment by November of this year. Subsequently, a team of Armstrong specialists traveled to MK’s production facility in Japan. They oversaw the precise installation and commissioning of the equipment and conducted thorough on-site training for MK’s technical personnel, ensuring seamless integration and optimal operational proficiency.

“We are honored to earn the trust of a distinguished industry leader like MK,” said a spokesperson for Armstrong. “Their visit and subsequent decision to partner with us validate the performance and reliability of our equipment. This project, from initial discussions to on-site implementation in Japan, has been a model of international cooperation. We extend our sincere gratitude to the MK team for their invaluable support and collaborative spirit throughout this process.”

MK Staff training and study CNC Grinding Machine

This partnership highlights Armstrong’s growing influence in the global automotive components supply chain and its ability to support top-tier manufacturers in achieving superior product quality and manufacturing excellence.

Partnering with an internationally recognized brand like MK is both a privilege and a profound responsibility. Their exacting standards for precision and performance serve not as a constraint, but as our most powerful catalyst for innovation. To meet and exceed their rigorous requirements, our Armstrong engineering team embarked on a dedicated process of targeted innovation and custom adaptation of our equipment.

This challenge has galvanized our confidence. It validates our core capability: the agility to delve deep into specific application needs—like the critical testing and manufacturing of brake components—and engineer solutions that deliver uncompromising accuracy, reliability, and consistency. The process of refining our technology for MK has further honed our expertise, solidifying our commitment to a singular goal: providing partners worldwide with equipment of the highest caliber. We are confident that this collaborative journey results in more than just a machine; it delivers a benchmark of quality engineered for excellence.

Post time: Dec-31-2025