Machining Center

Application:

Kugadzirisa dhizaini yekumashure mushure mekucheka laser.Kana ukashandisa laser yekucheka muchina kuvhara uye kugadzira maburi, saizi yeplate yekumashure ichava nemusiyano mudiki, nekudaro isu tinoshandisa machining Center kugadzirisa zvakanaka ndiro yekumashure sechikumbiro chekudhirowa.

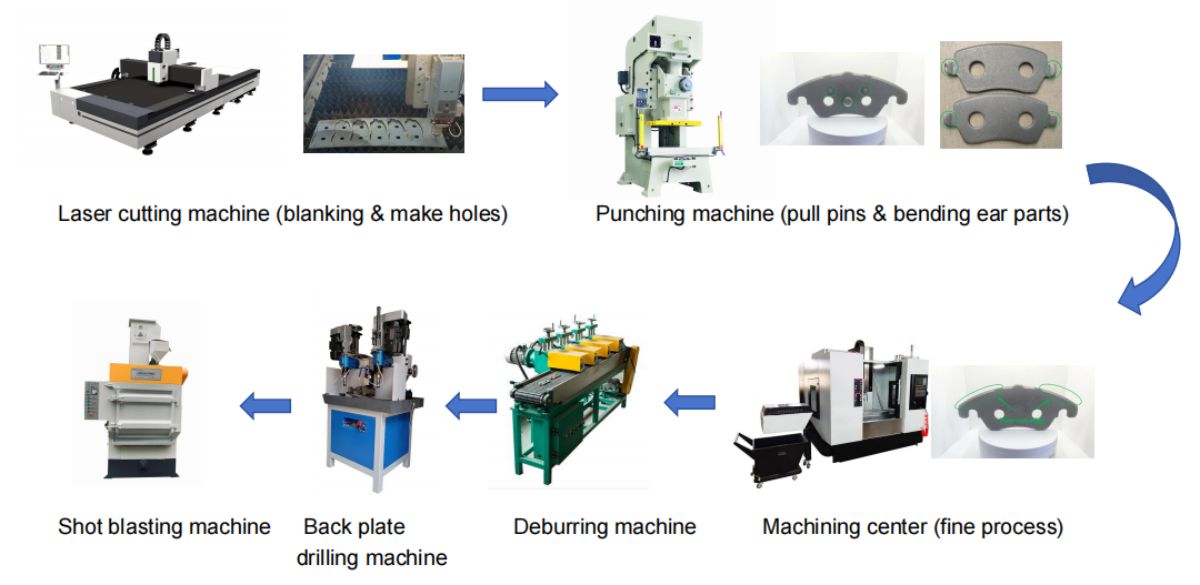

PC Back Plate Production Flow

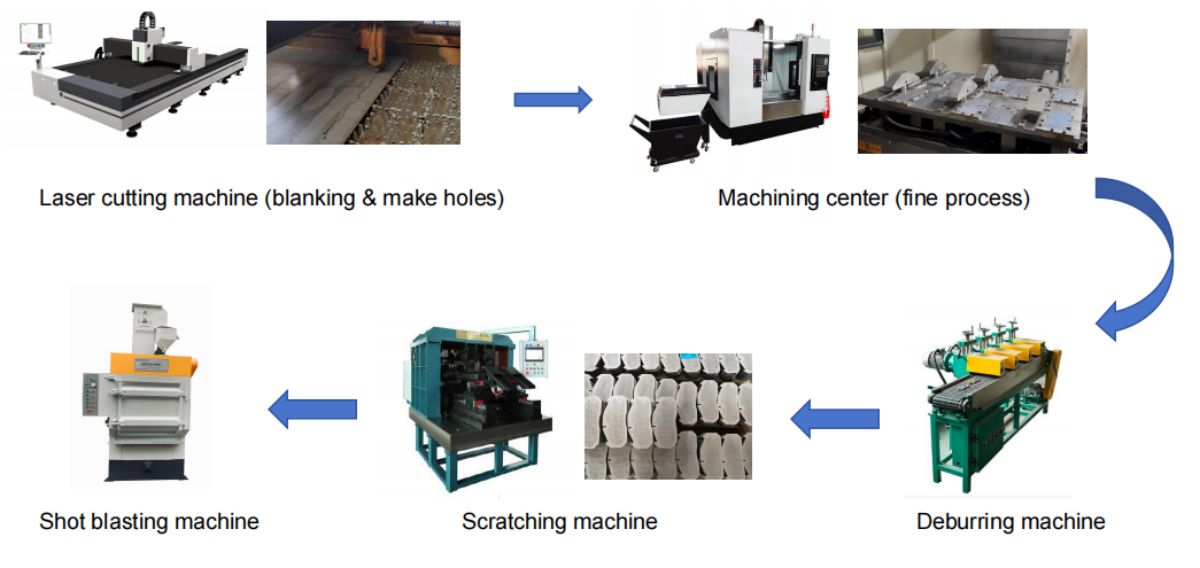

CV Back Plate Production Flow

Zvatinazvo:

Kuomarara kwakasimba: Nzvimbo yespindle yenzvimbo yakatwasuka machining yakakwira, uye ndiro yekumashure inosungirirwa pabhenji rebasa, zvichiita kuti machining awedzere kuomarara uye anokwanisa kubata mahwendefa ekumashure akaomarara uye masimba ekucheka epamusoro.

Yakanaka machining kugadzikana: Nekuda kweiyo yepamusoro spindle chinzvimbo cheiyo vertical machining center, machining uye kucheka kweplate yekumashure yakanyanya kugadzikana, iyo inobatsira kuvandudza machining kurongeka uye kunaka kwepamusoro.

Kushanda kuri nyore: Workpiece clamping uye kutsiva chishandiso zvese zvinoitwa panzvimbo yekushanda, zvichiita kuti zvive nyore kune vashandisi kutarisa nekuchengetedza.

Diki tsoka: Iyo yakatwasuka machining centre ine compact chimiro uye ikati diki tsoka, ichiita kuti ive yakakodzera kumashopu ane nzvimbo shoma.

Mutengo wakaderera: Kana ukashandisa punching muchina we back plate yakanaka process, isu tinofanirwa kugadzira yakanaka yekucheka stamping kufa kune yega yega modhi, asi machining centre inongoda chibatiso chekuisa kumashure mahwendefa.Inogona kuchengetedza mold invest kune mutengi.

Kunyanya kushanda zvakanaka: Mumwe mushandi anogona kudzora 2-3 seti machining Center panguva imwe chete.