Machining Center

Application:

To fine process the back plate after laser cutting. If use laser cutting machine to blanking and make holes, the back plate size will have tiny difference, thus we use machining center to fine process the back plate as drawing request.

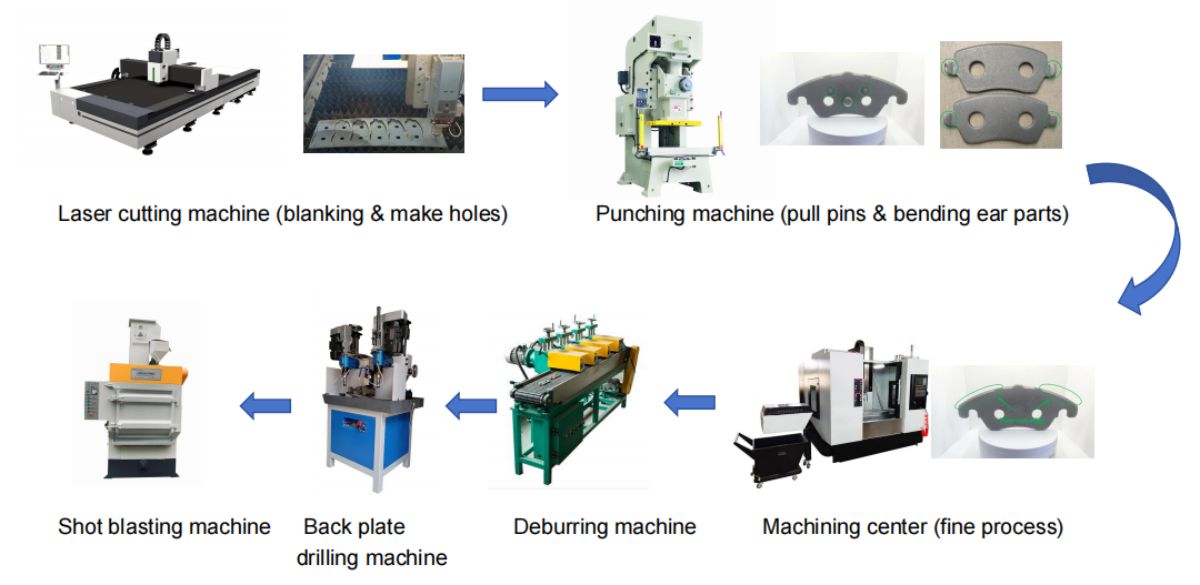

PC Back Plate Production Flow

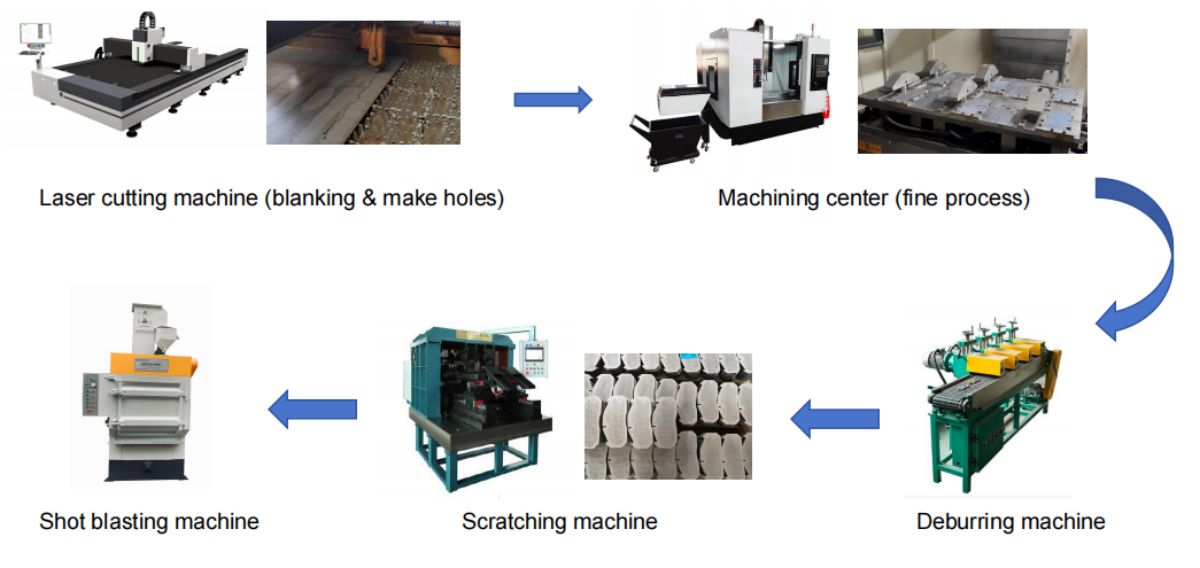

CV Back Plate Production Flow

Our Advantages:

Strong rigidity: The spindle position of the vertical machining center is higher, and the back plate is clamped on the workbench, making the machining process more rigid and capable of handling more complex back plates and higher cutting forces.

Good machining stability: Due to the higher spindle position of the vertical machining center, the machining and cutting process of the back plate is more stable, which is conducive to improving machining accuracy and surface quality.

Convenient operation: Workpiece clamping and tool replacement are all carried out on the operating surface, making it easy for operators to monitor and maintain.

Small footprint: The vertical machining center has a compact structure and a relatively small footprint, making it suitable for workshops with limited space.

Low cost: If use punching machine for back plate fine process, we need to make fine cut stamping die for each model, but machining center only requires a clamp to place back plates. It can save mold invest for customer.

High efficiency: One worker can control 2-3 sets machining center at same time.