High temperature curing oven

After hot press section, the friction material will bind on the back plate, which forming the general shape of the brake pad. But only a short heating time in press machine is not enough for friction material to be solid. Usually it needs high temperature and long time for friction material to bind on back plate. But the curing oven can greatly reduces the time needed for curing friction materials, and increases the shear strength of brake pads.

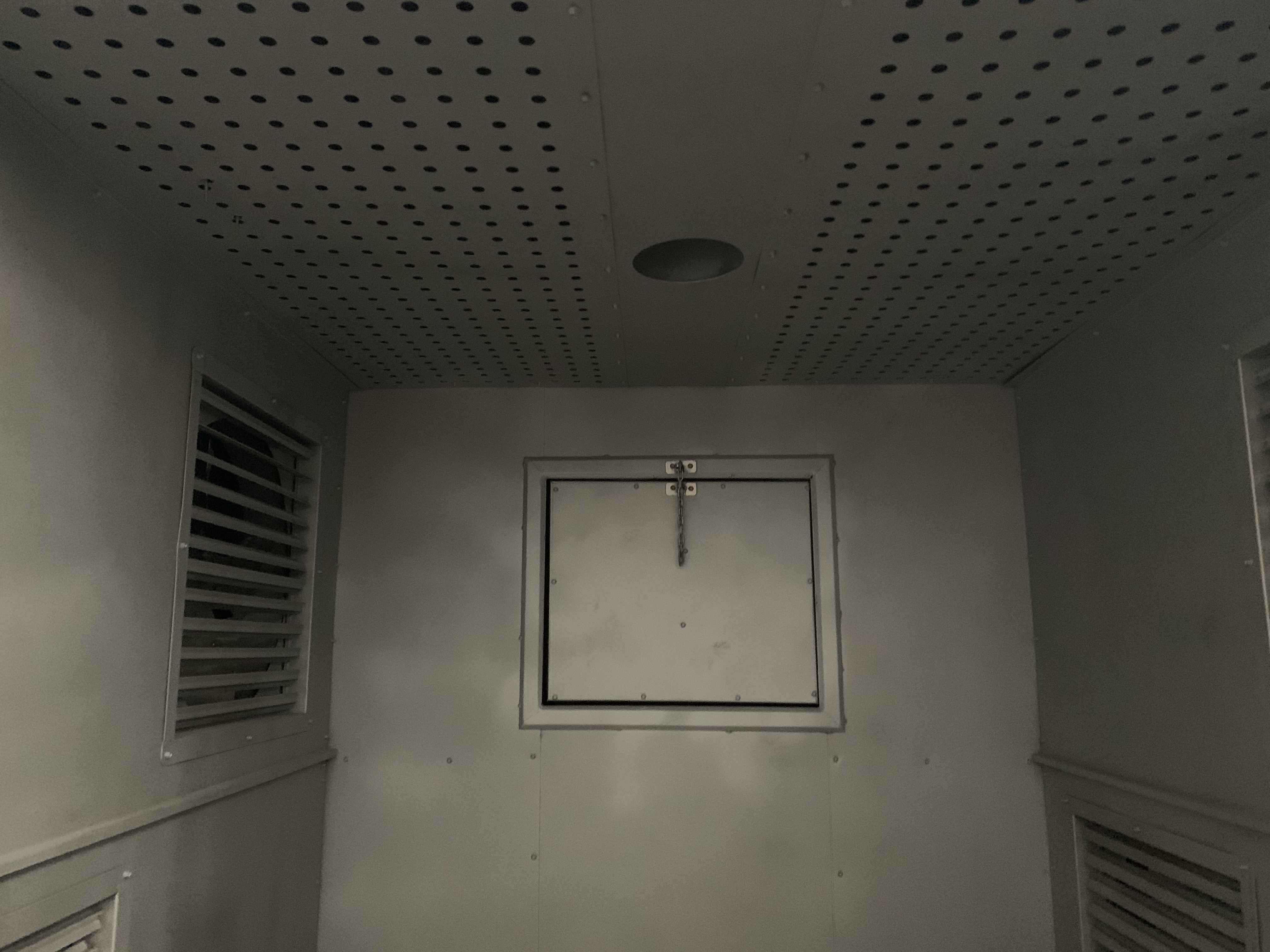

The curing oven takes the fin radiator and heating pipes as the heat source, and uses the fan to heat the air by convection ventilation of the heating assembly. Through the heat transfer between the hot air and the material, the air is continuously supplemented through the air inlet, and the wet air is discharged out of the box, so that the temperature in the furnace is continuously increased, and the brake pads are gradually preheated.

The design of the hot air circulation duct of this curing oven is ingenious and reasonable, and the hot air circulation coverage in the oven is high, which can evenly heat each brake pad to achieve the effect required for curing.

The oven provided by the supplier is a mature and brand-new product, which meets the national standards and various technical requirements signed in this technical agreement. The supplier shall ensure that the ex factory products are strictly tested, with stable and reliable performance and complete data. Each product is the embodiment of perfect quality and creates better value for the demander.

In addition to the selection of raw materials and components specified in this agreement, the suppliers of other purchased parts need to select manufacturers with good quality, good reputation and in line with national or relevant technical standards, and strictly test all purchased parts according to the provisions of ISO9001 quality management system.

The Demander shall use the equipment according to the operating procedures indicated in the product operation manual and precautions for product use and maintenance provided by the supplier. If the demander fails to use according to the operating procedures or fails to take effective safety grounding measures, resulting in damage to the baked workpiece and other accidents, the supplier shall not be liable for compensation.

The supplier provides the demander with all-round first-class services before, during and after sales. Any problem occurred during the installation or operation of the product shall be replied within twenty-four hours after receiving the user's information. If it is necessary to send someone to the site to solve it, the personnel shall be on site to deal with the relevant problems within 1 week to make the product operate normally.

The supplier promises that the product quality will be maintained free of charge within one year from the date of delivery of the product and lifelong service.