KRAUSS friction material testing machine

1.Main functions:

1. Friction and wear performance test for car brake pads & shoes.

2. It has the function of constant torque test

3. Optional static torque test function (including parking)

4. Optional water spraying performance test

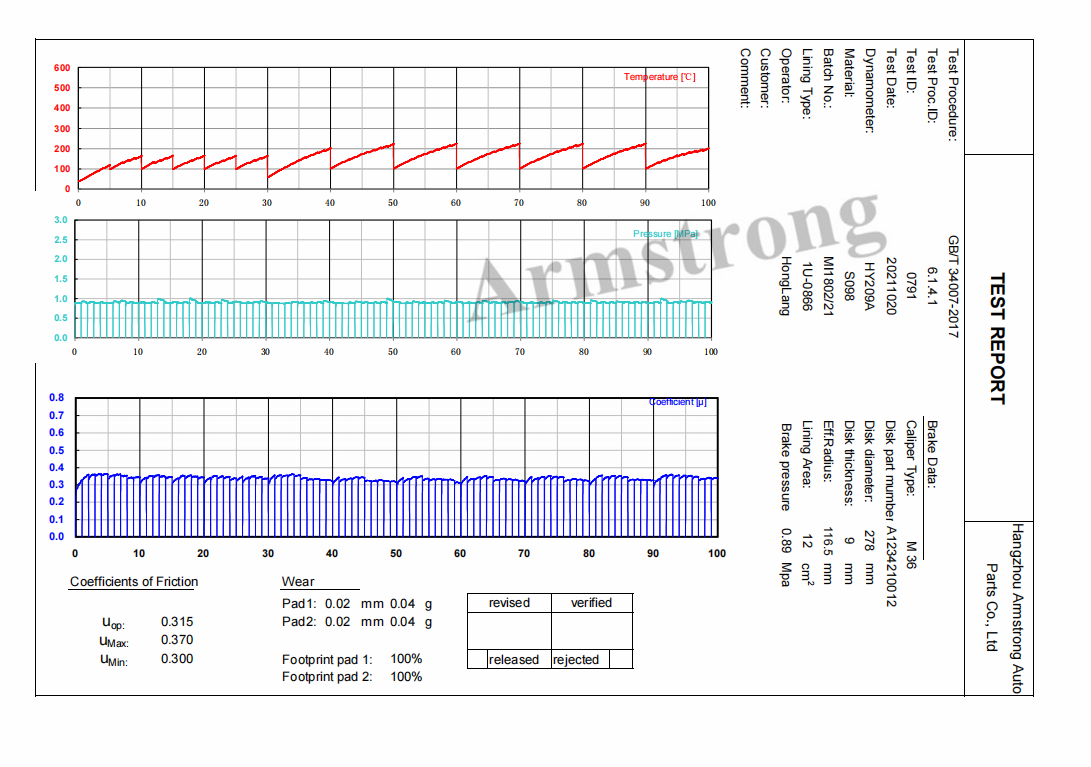

5. All are tested and controlled by computer. Users can prepare various standard and non-standard test specifications by themselves

6. Standard curve output and test report printing

7. Test standard: GBT34007, ECE R90

2.Product Detail:

Instead of bevel gear transmission, it is replaced by direct transmission with triangular belt, which reduces noise pollution.

The unloading handle is added to facilitate the loading and unloading of the test piece.

Changing the calibration of spring tension meter to gravity weight calibration, which reduces the influence of human factors and improves the calibration accuracy.

Stainless steel heating and cooling cover is adopted, all wet water parts are chrome plated for rust prevention, and stainless steel nickel chromium wire electric heating tube is adopted to prolong the service life.

HT250 precision cast friction disc is tested before the electric furnace, which improves the comparability of test data.

The tension and compression sensor is used to replace the force measuring spring to measure the friction. The friction coefficient is calculated and displayed by computer. At the same time, the relationship between friction coefficient, temperature and revolution is displayed, and the measurement accuracy of friction is improved.

The temperature control of friction disc is changed from manual control to computer automatic control, which improves the temperature control accuracy, is simple to operate, reduces the labor intensity, and can realize off machine test.

Electric heating and water cooling devices are arranged under the friction disc.

The software operating system adopts windows system, and the test operation adopts man-machine dialogue; The operation is simple and convenient. The test status can be displayed in the form of curve through the computer interface, which is intuitive and clear.

Test data and curves can be saved, printed, and can also be called out at any time.