Combined grinding machine for PC brake pad

Main operation steps:

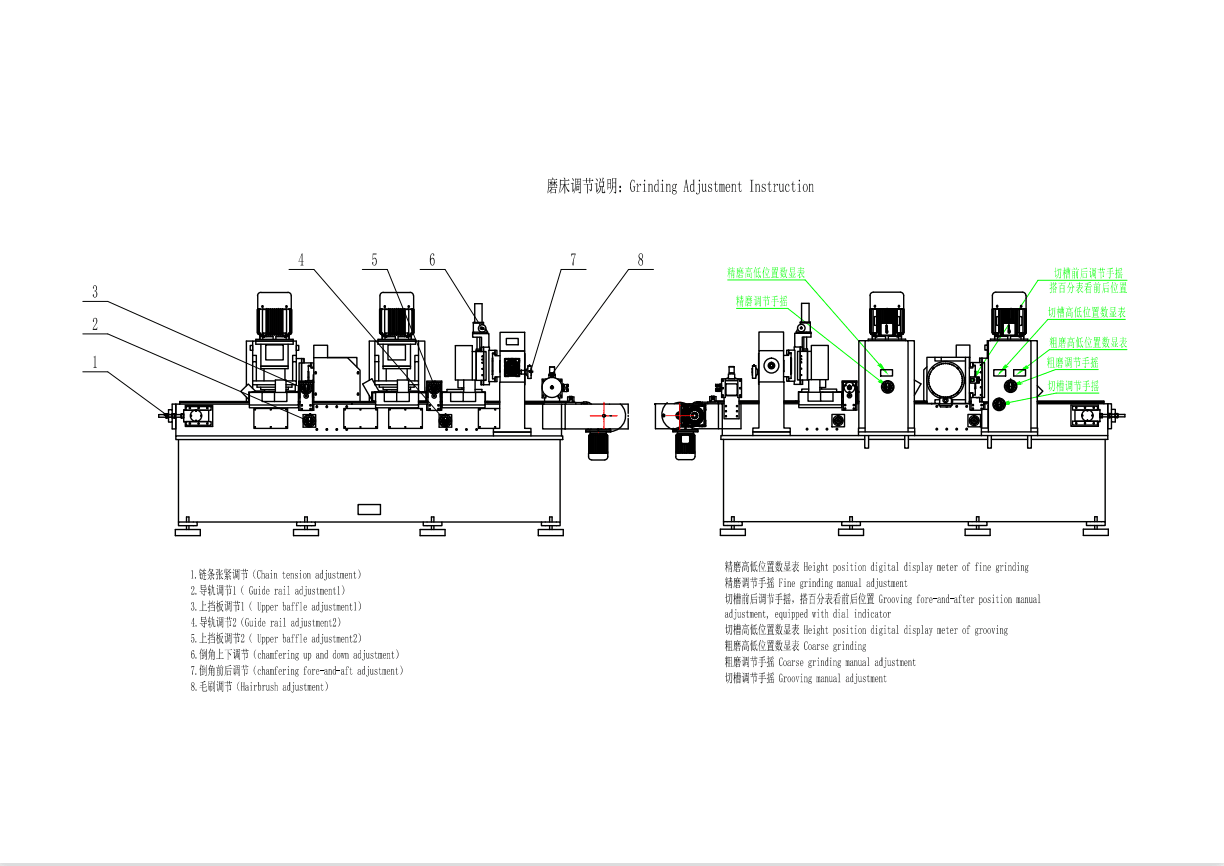

a. Adjust the grinding quantity:

The grinding amount is adjusted by turning the adjusting hand wheel to change the distance between the grinding surface and the white steel track. The upper and lower dimensions are adjusted by a light ruler (the precision of the light ruler is 0.01mm) and locked by a locking handle.

b. Workflow (step by step)

1. Open the dust suction and the main switch, then turn on the power button, turn on the rough grinding, grooving, fine grinding, angle chamfering, ash brushing and conveying in sequence.

2. Lift the grinding head motor, grooving motor and chamfering motor to a certain height and slightly adjust according to your need.

3. Check the product size and grinding size, calculate the total grinding size.

4. Reduce (adjust grinding amount) the coarse grinding motor to 80% of the total grinding amount.

5. Lower (adjust the groove depth) the groove motor to the size requirements.

6. Reduce (adjust grinding amount) fine grinding motor to 20% of the total grinding amount.

7. Reduce (adjust grinding height) in and out (adjust grinding width) chamfering motor to product size requirements.

8. Adjust frequency conversion transmission according to the output requirements.

9. Shutdown the conveying, ash brushing, angle chamfering, fine grinding, grooving, rough grinding motor and then turn off the power switch, pull down the main switch.

CGM-P600 conveying linear grinder is a special machine tool for surface processing of friction materials of vehicle disc brake pads. It is suitable for grinding, grooving, angle chamfering and ash brushing of various types of disc pads, which can ensure the surface roughness, parallelism and other requirements of friction pads.

It is a machining machine tool integrating rough grinding, grooving, fine grinding, chamfering, ash brushing and turnover. It has high production efficiency and stable quality. This machine is also suitable for the needs of mass production. It has the characteristics of simple operation, easy adjustment, high precision and continuous feed pieces.

The whole machine is composed of base, conveyor, rough grinding assembly, grooving assembly, fine grinding assembly, chamfering assembly, ash brushing assembly, turnover mechanism and dust suction assembly.

The working principle of the machine is that the brake disc is pushed into the permanent magnet white steel guide rail by the conveying push strip, and then through rough grinding, grooving, fine grinding, angle chamfering, ash brushing. Finally the brake disc would be overturned in the automatic turning mechanism, and enter the next process.