Tshuab sib tsoo ua ke rau PC nres pad

Cov kauj ruam ua haujlwm tseem ceeb:

a. Kho qhov sib tsoo kom raug:

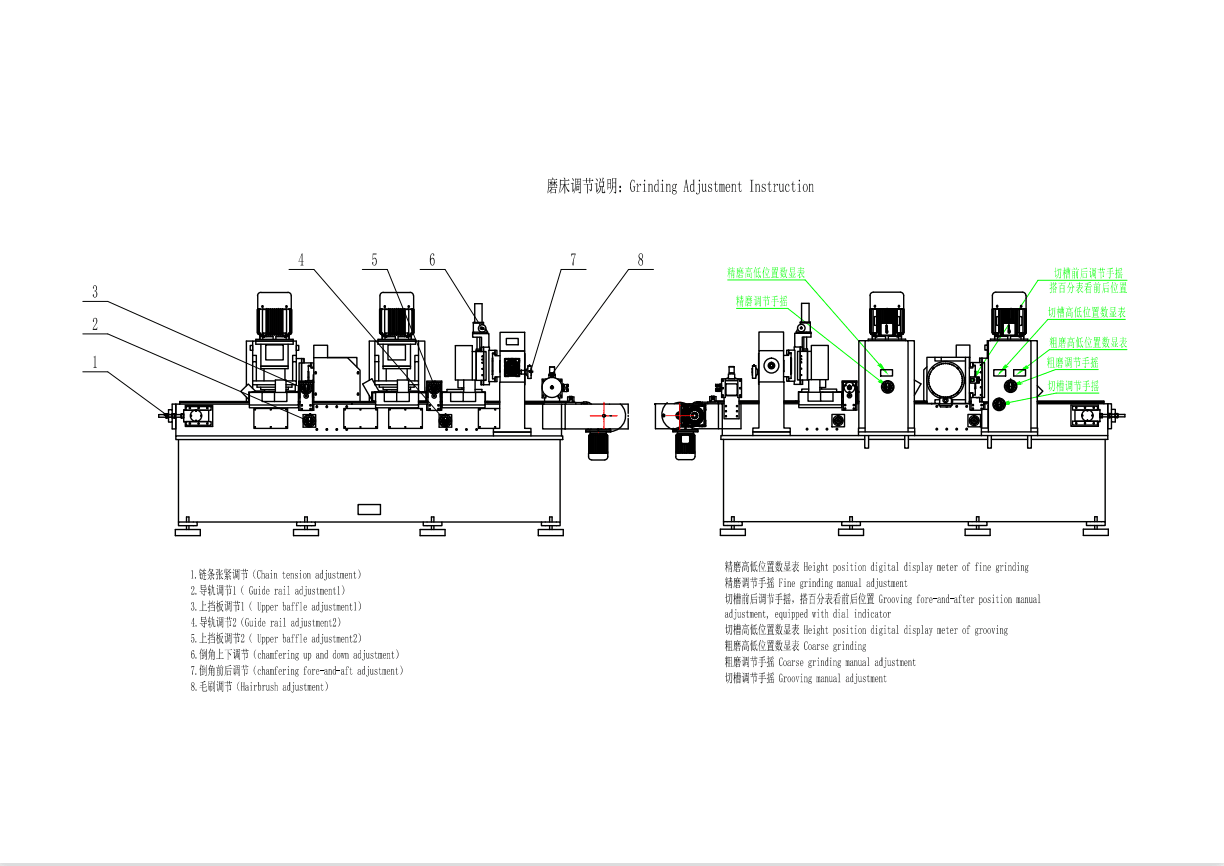

Qhov sib tsoo ntau npaum li cas yog kho los ntawm kev tig lub log tes kho kom hloov qhov deb ntawm qhov chaw sib tsoo thiab txoj kab hlau dawb. Qhov loj sab saud thiab sab hauv qab yog kho los ntawm tus pas ntsuas teeb (qhov tseeb ntawm tus pas ntsuas teeb yog 0.01 hli) thiab xauv los ntawm tus kov xauv.

b. Kev Ua Haujlwm (kauj ruam zuj zus)

1. Qhib lub tshuab nqus plua plav thiab lub qhov hloov tseem ceeb, tom qab ntawd tig rau lub pob hluav taws xob, tig rau qhov sib tsoo ntxhib, grooving, sib tsoo zoo, lub kaum sab xis chamfering, txhuam tshauv thiab xa khoom raws li qhov sib lawv liag.

2. Nqa lub cav sib tsoo taub hau, lub cav grooving thiab lub cav chamfering mus rau qhov siab thiab kho me ntsis raws li koj xav tau.

3. Tshawb xyuas qhov loj ntawm cov khoom thiab qhov sib tsoo loj, xam tag nrho qhov loj ntawm kev sib tsoo.

4. Txo (kho qhov sib tsoo) lub cev muaj zog sib tsoo kom txog 80% ntawm tag nrho cov nyiaj sib tsoo.

5. Txo (kho qhov tob ntawm qhov zawj) lub cav zawj kom raws li qhov loj me uas xav tau.

6. Txo (kho qhov sib tsoo) lub cev muaj zog sib tsoo kom txog 20% ntawm tag nrho cov nyiaj sib tsoo.

7. Txo (kho qhov siab sib tsoo) rau hauv thiab tawm (kho qhov dav sib tsoo) lub cev muaj zog kom raws li qhov loj ntawm cov khoom xav tau.

8. Kho qhov kev hloov pauv zaus raws li qhov yuav tsum tau tso zis.

9. Kaw qhov kev xa khoom, txhuam tshauv, lub kaum sab xis chamfering, sib tsoo zoo, grooving, sib tsoo ntxhib thiab tom qab ntawd tua lub hwj chim hloov, rub lub qhov hloov tseem ceeb.

CGM-P600 conveying linear grinder yog lub cuab yeej tshuab tshwj xeeb rau kev ua cov khoom siv sib txhuam ntawm cov disc nres pads. Nws yog qhov tsim nyog rau kev sib tsoo, grooving, lub kaum sab xis chamfering thiab txhuam tshauv ntawm ntau hom disc nres pads, uas tuaj yeem ua kom qhov roughness ntawm qhov chaw, parallelism thiab lwm yam kev xav tau ntawm kev sib txhuam pads.

Nws yog ib lub tshuab ua haujlwm uas muaj kev sib xyaw ua ke ntawm kev sib tsoo ntxhib, kev sib tsoo grooving, kev sib tsoo zoo, kev sib tsoo chamfering, kev txhuam tshauv thiab kev tig. Nws muaj kev ua haujlwm siab thiab ruaj khov. Lub tshuab no kuj tsim nyog rau kev xav tau ntawm kev tsim khoom loj. Nws muaj cov yam ntxwv ntawm kev ua haujlwm yooj yim, kev kho yooj yim, kev raug siab thiab kev pub khoom tas mus li.

Tag nrho lub tshuab yog tsim los ntawm lub hauv paus, conveyor, sib tsoo ntxhib, sib dhos grooving, sib tsoo zoo, sib dhos chamfering, sib dhos txhuam tshauv, tig mechanism thiab sib dhos nqus plua plav.

Lub hauv paus ntsiab lus ua haujlwm ntawm lub tshuab yog tias lub disc nres raug thawb rau hauv lub hlau nplaum dawb hlau qhia kev tsheb ciav hlau los ntawm daim ntawv thawb xa khoom, thiab tom qab ntawd los ntawm kev sib tsoo ntxhib, grooving, sib tsoo zoo, lub kaum sab xis chamfering, thiab txhuam tshauv. Thaum kawg lub disc nres yuav raug tig rov qab hauv lub tshuab tig tsis siv neeg, thiab nkag mus rau cov txheej txheem tom ntej.