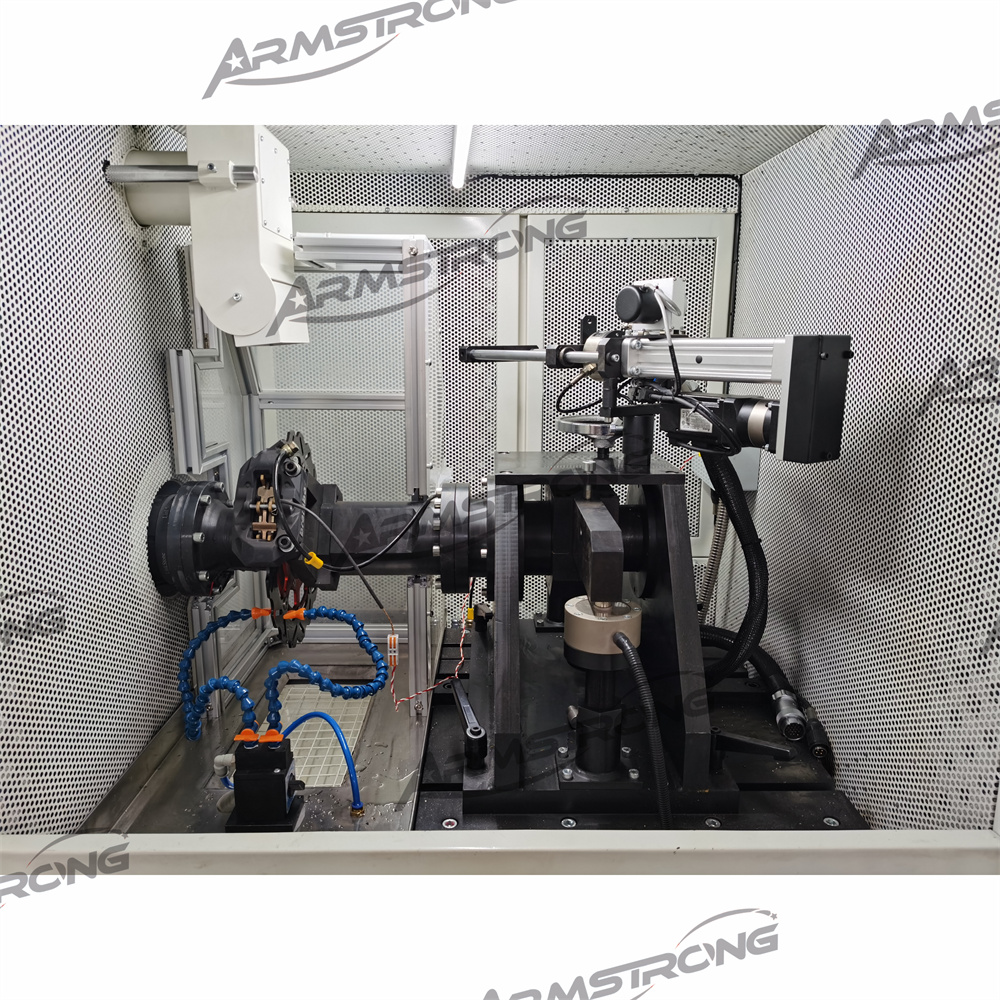

Motorcycle Brake Caliper Dynamometer

Application:

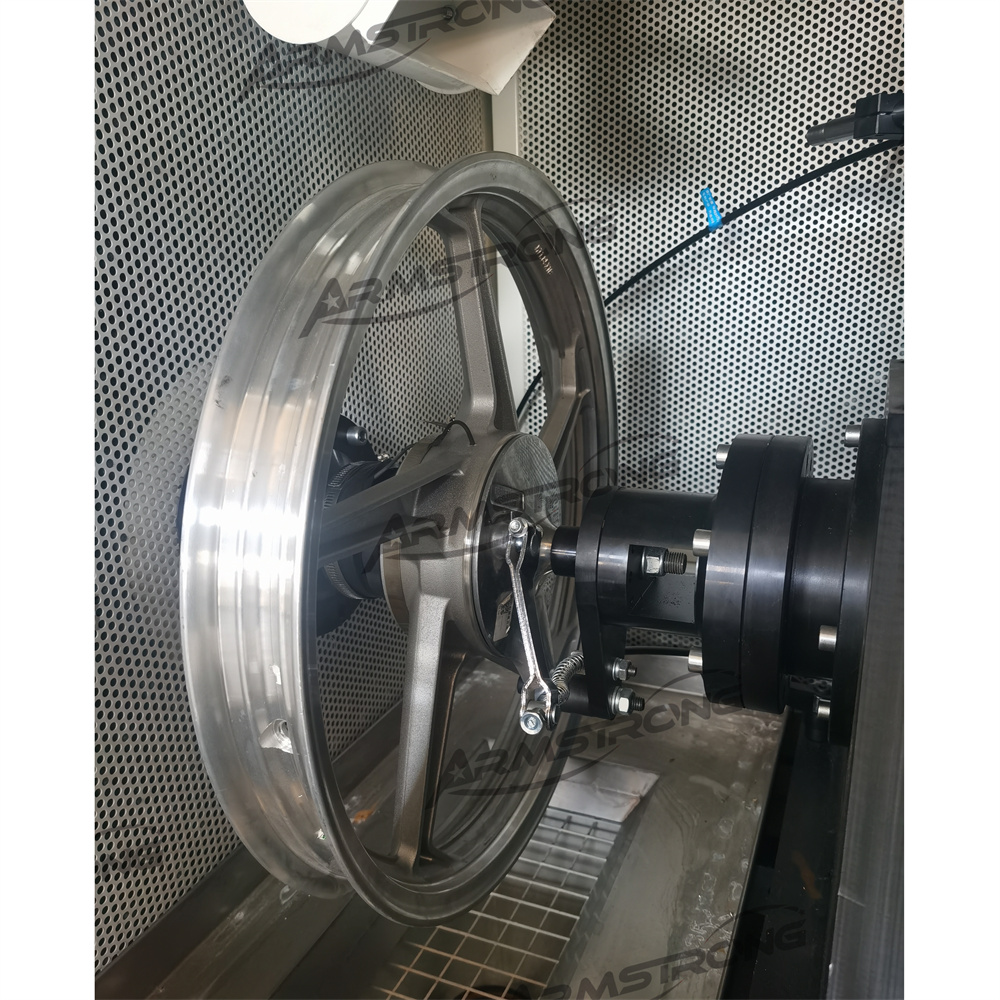

In the field of motorcycle design and manufacturing, the performance of the braking system is directly related to the personal safety of the rider. The traditional brake testing methods have many limitations, but the emergence of electric simulation inertia test benches has brought revolutionary changes to the development and testing of motorcycle brakes. This dynamometer is especially designed for motorcycle brake pad and brake shoes, to test the brake performance and noise value during real situation brake.

Product Detail:

The motorcycle brake caliper dynamometer is a high-performance testing equipment that replaces traditional mechanical inertia through electric simulation. Its main functions are reflected in the following aspects:

●Accurate simulation of real working conditions: able to accurately reproduce the inertia characteristics of motorcycles at different speeds, including braking conditions under various speed conditions.

●Comprehensive performance evaluation: It can test key indicators such as braking torque, braking distance, braking stability, and thermal degradation performance of the brake.

●Durability testing: Simulate the performance changes of the brake under long-term use conditions to evaluate the product's service life.

●Extreme condition testing: safely simulate braking performance in extreme environments such as wet and slippery roads, high temperatures, and low temperatures.

●R&D support: Provide reliable experimental data support for the design of new brake materials and brake structures.

Technical principles and system composition:

●The electric simulation inertia test bench adopts advanced power electronics technology and precise control algorithms to simulate the inertia of traditional flywheels:

●Electric inertia simulation system: By accurately controlling the motor torque, real-time calculation and simulation of dynamic characteristics under different inertia.

●High dynamic response motor: using servo motor or variable frequency motor system to provide fast torque response.

●Data acquisition system: high-precision sensors monitor real-time parameters such as braking force, speed, temperature, etc.

●Control system: A closed-loop control system based on advanced algorithms to ensure the accuracy of the testing process.

Advantages:

2.1 Stepless inertia adjustment: The test inertia can be set arbitrarily within the maximum inertia range, without the need for mechanical adjustment. One device can cover the full range of testing requirements from light to heavy motorcycles.

2.2 Revolutionary improvement in testing efficiency: eliminates the time for traditional equipment to accelerate the flywheel, shortens the testing cycle by more than 60%, and greatly improves the efficiency of research and quality inspection.

2.3 Intelligent testing: integrating advanced testing software, supporting automated testing processes, intelligent data analysis, automatic report generation, and other functions.

2.4 Safe and reliable: Avoiding the safety hazards of high-speed rotating flywheels, the testing process is completely controllable.

2.5 Strong scalability: Testing functions can be added through software upgrades to adapt to future new testing standards and requirements.

2.6 All parts adopts famous brand, for example ACC motor and IPC Energy feedback unit, make sure test result accuracy.

2.7 Can test both brake pad and brake shoe product performance.

- Partial technical parameters:

|

Main Technical parameters |

|

|

Motor power |

30Kw three-phase AC variable frequency speed control motor |

|

Main shaft speed |

5-2000 rpm |

|

Test inertia |

25kgm² (mechanical inertia) ±5kgm² (electrical simulation) |

|

Maximum operating torque |

≤1000N.m |

|

Braking pressure |

≤ 160bar |

|

Constant torque |

50-600N.m |

|

Temperature measurement |

room temperature ~1000℃ |

|

Cooling system |

wind speed ≤10m/s (simulated setting) |

|

Computer system |

Siemens industrial control computer 19-inch industrial LCD display A4 color printer |

|

Machine Functions |

|

|

1 |

Electric inertia simulation function |

|

2 |

Brake noise testing function |

|

3 |

Test function with constant torque (constant output) |

|

4 |

Test function with constant pressure (constant input) |

|

5 |

Cold air speed simulation function |

|

6 |

Braking efficiency test function |

|

7 |

High temperature decay+recovery test function |

|

8 |

Water degradation+recovery test function |

|

9 |

Comprehensive computer control, inspection, printing of curves and reports |

|

10 |

The software is fully programmable and can execute testing standards from China, Europe, the United States, Japan, and other countries |