Welcome to our websites!

News

-

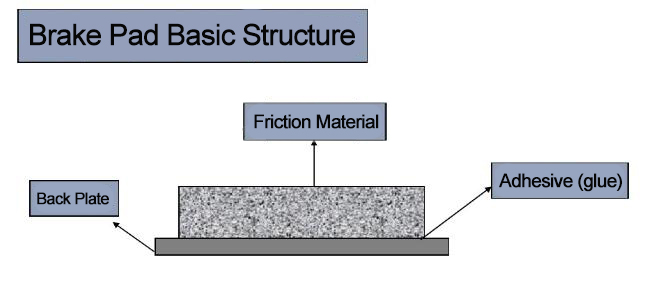

Beyond the Basics —— The Hidden Components in Brake Pads

When most drivers think of brake pads, they envision two main parts: the sturdy steel backing plate and the friction material that presses against the rotor. However, modern brake pads are sophisticated safety assemblies that often incorporate several additional, crucial components. Under...Read more -

From Blueprint to Output: Armstrong Delivers Turnkey Brake Line for Bangladesh Military

We at Armstrong are delighted to extend our warmest congratulations on the successful establishment of a professional brake pad and brake shoe production line for a military enterprise in Bangladesh. This groundbreaking achievement marks the creation of the country’s first manufacturer with...Read more -

From Factory Tour to On-Site Installation

——How Armstrong Empowered MK Kashiyama Brake Production in 2025 MK Kashiyama is a distinguished and technologically advanced manufacturer in Japan’s automotive components sector, renowned for its high-performance brake pads that prioritize safety, durability, and precision engineering. Wit...Read more -

What affects Brake Pad Shear Strength?

Brake pad shear strength: the invisible guardian of safe driving Brake pads, as key components of automotive braking systems, have a direct impact on driving safety in terms of their performance. Shear strength is one of the important indicators for measuring the perfor...Read more -

UV Ink-jet Printer VS Laser Printing Machine

Manufacturers will print brand logo, production model and date on brake pad back plate side. It has many advantages for manufacturer and customers: 1.Quality Assurance and Traceability Product identification and branding can help consumers identify the source of brake ...Read more -

Why Brake Pads Rust and How to Prevent this Issue?

If we park the car outdoors for long time, you could find the brake disc would be rusty. If in damp or rainy environment, the rust would be more obvious. Actually rust on vehicle brake discs is usually the result of the combined effect of their material and usage environ...Read more -

Brake Pad Back Plates: Punching VS Laser Cutting?

Steel back plate is an important part of brake pads. The main function of the brake pad steel back plate is to fix the friction material and facilitate its installation on the brake system. In most modern cars, especially those that use disc brakes, high-strength frictio...Read more -

Truck Brake Pads Back Plate Types

Brake pads are important components installed in automotive, which slow down or stop the vehicle by generating friction with the wheels. When the brake pedal is pressed, the brake pads will come into contact with the brake disc (or drum), thereby suppressing the rotation of the wheels. The effect...Read more -

Hot Press Machine: Casting VS Welding technology

Hot press is the most important and necessary step in both brake pad and brake shoe friction linear production. The pressure, heat temperature and exhaust time will all affect brake pad performance. Before buying a hot press machine which suitable for our own products, we must first have a full u...Read more -

Brake Pads: Knowing the raw material and formula

To make the high quality brake pads, there’s two important parts: back plate and raw material. Since the raw material (friction block) is the part directly touch with brake disc, it’s type and quality plays an important role in brake performance. In fact, there are hundreds of raw material types ...Read more -

Dust removal and environmental protection measures

During the brake pad production process, especially the friction material mixing and brake pads grinding process, it will cost huge dust in the workshop. In order to make the working environment clean and less dust, some of the brake pad making machines need to connect w...Read more -

What is difference between Powder Coating and Paint Spraying?

Powder coating and paint spraying are two processing technic in brake pad production. Both function is to form a protective cover on the surface of the brake pad, which has following advantages: 1. Effectively isolate the contact between steel back plate and air / water ...Read more