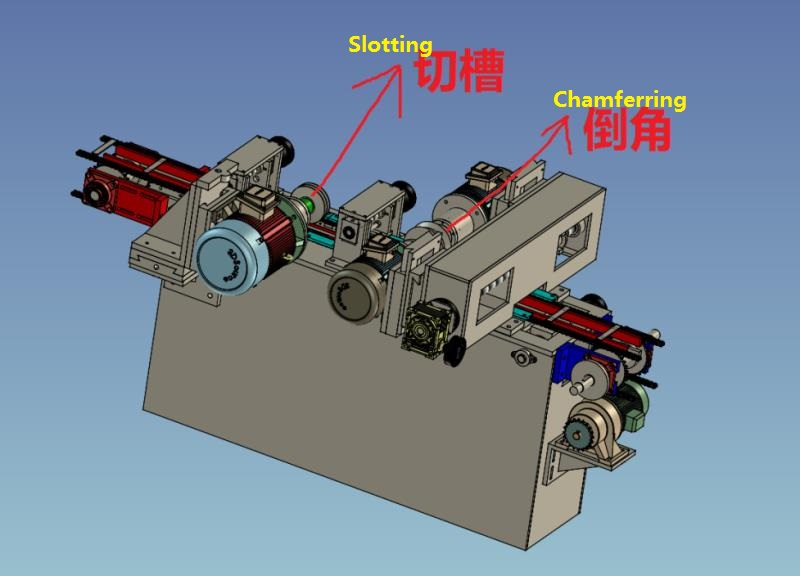

Slotting & Chamfering machine

Slotting and Chamfering are 2 steps for brake pad processing.

Slotting is also called grooving, it means make several grooves on

the brake pad friction material side, and different brake pad models has different groove number. For example, motorcycle brake pads usually has 2-3 grooves, while passenger car brake pads usually has 1 groove.

Chamfering is the process to cut angles on the friction block edge. Like slotting grooves, chamfering also has different requirements of cutting angles and thickness.

But why does these two steps are necessary? Actually it has following advantages:

1. Reduce noise by changing the frequency of the oscillation frequency level.

2. Slotting also provides a channel for gas and dust to be emitted in high temperature, effectively reducing the decline of braking efficiency.

3. In order to prevent and reduce cracking.

4. Make the brake pads more beautiful on appearance.