Welcome to our websites!

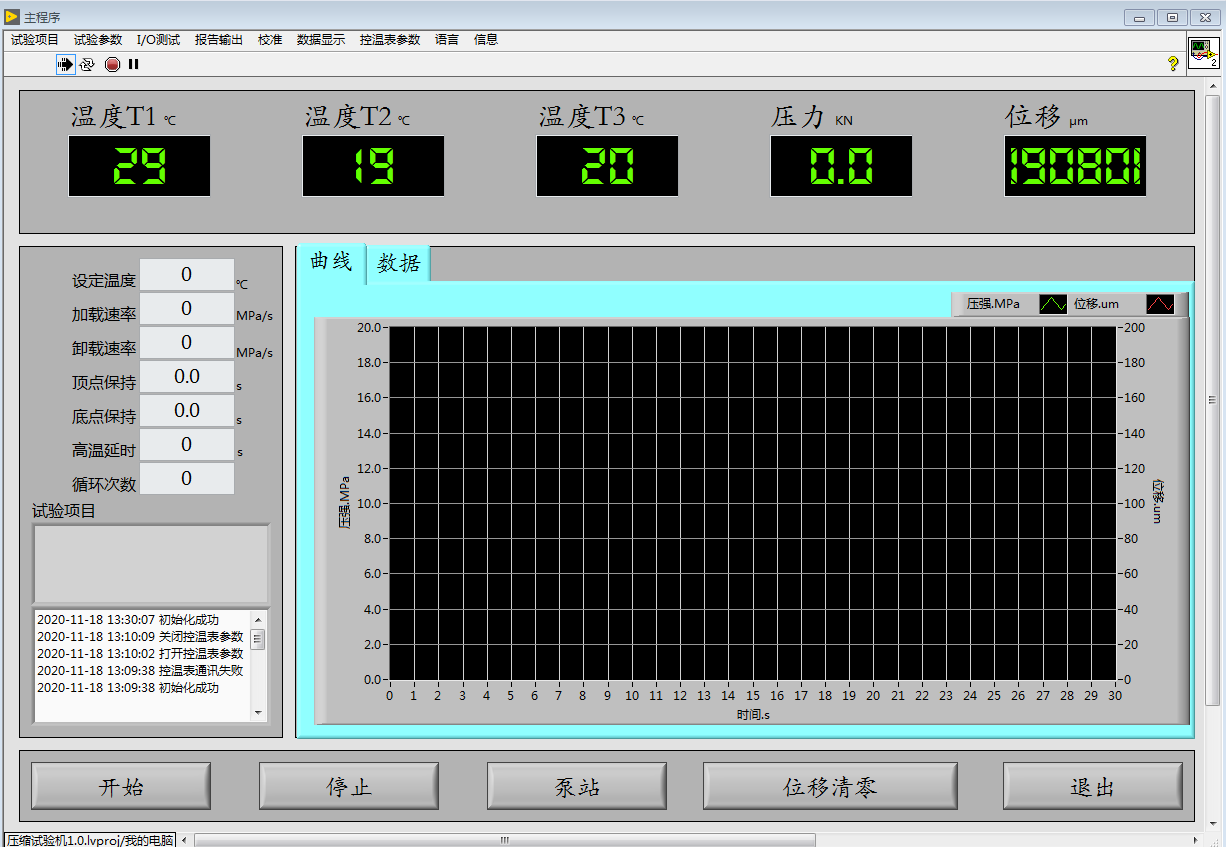

Compressibility machine

|

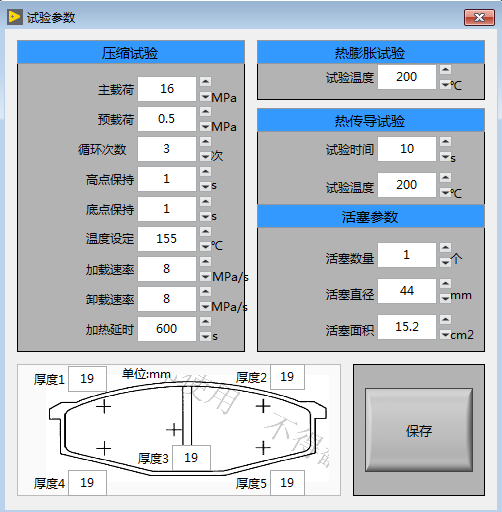

Technical parameters |

|

| Hydraulic cylinder stroke | 60 mm |

| Hydraulic cylinder piston stroke | 90 mm |

| Grating micrometer sensor stroke | 20 mm |

| Measure accuracy | 0.001 mm |

| Loading range | 0~16MPa(0~10t) |

| Loading vertical pressure | Max. 80 KN |

| Pressure block adjustment range | 0~40 mm |

| Loading speed | 1~75 KN/s |

| Heating plate power | 350W*9 |

| Heating plate temperature | ≤500℃ |

| Heating plate dimension | 180*120*60 mm |

| Main power | 3P, 380V/50Hz, 3KVA |

| Cooling water | Normal industrial water |

| Environmental temperature | 10℃~40℃ |

| Machine dimension (L*W*H) | 1700*800*1800 mm |

| Weight | 300 KG |