Mochine oa khatiso o chesang ke mohato oa bohlokoa ka ho fetisisa le o hlokahalang ho bobeli ba brake pad le brake shoe friction linear production.Khatello, mocheso oa mocheso le nako ea ho qeta kaofela li tla ama ts'ebetso ea brake pad.Pele re reka mochini oa khatiso o chesang o loketseng lihlahisoa tsa rona, re tlameha ho qala ho ba le kutloisiso e felletseng ea mochini oa khatiso o chesang.

(Liparamente li rarollotsoe ka skrine ea ho ama)

Mochine oa khatiso o chesang le oa ho cheselletsa o chesang ke mekhoa e 'meli e fapaneng ka ho feletseng ea tlhahiso ea khatiso e chesang, e nang le phapang e kholo ea molao-motheo, ts'ebeliso le ts'ebetso.

Mochini oa khatiso o chesang ke mokhoa oa tlhahiso o kenyelletsang ho qhibilihisa tšepe ka mocheso o phahameng le likhatello, le ho e kenya ka har'a hlobo ho etsa sebopeho se lakatsehang.E sebelisa matla a mocheso le khatello ea ho holofatsa le ho tiisa thepa.Kahoo ho etsa moqomo o ka sehloohong, boloko bo thellang le botlaaseng.Nakong ea ts'ebetso, e hloka ho lokisa hlobo, ho futhumatsa thepa, ho laola mocheso le khatello, le likarolo tse ling, ebe o kenya thepa ka har'a hlobo ebe o emela hore thepa e tiee pele e tlosa likarolo.

Empa bakeng sa mochini oa khatiso o chesang o chesang, mokhoa oa ho etsa o fapane ka ho felletseng:

1) Bakeng sa moqomo o ka sehloohong, o entsoe ka tšepe e pota-potileng ea boleng bo holimo ka ho forging (ho ntlafatsa sebopeho sa mokhatlo o hlophisitsoeng oa thepa le matla a ntseng a eketseha) - ebe o sebelisa mochini oa ho itšeha oa laser ho cheka lehare le ka hare - welding ka Q235 tšepe ea boleng bo holimo. - ka kakaretso ho tima le ho kokobetsa phekolo (ho felisa khatello ea kelello ka hare) - ts'ebetso e ntle.

2) Bakeng sa li-sliding block le setsi se ka tlase: sebelisa Q235 tšepe ea boleng bo phahameng bakeng sa welding (mochini o teteaneng oa ho cheselletsa poleiti, matla Factor of Safety ke makhetlo a fetang 2) - ho tima le ho fokotsa phekolo (ho felisa khatello ea kelello ka hare) - ho sebetsa hantle.

Ka bokhutšoanyane, mochine oa khatiso oa ho lahla le oa ho cheselletsa ke mekhoa e fapaneng ea tlhahiso e entsoeng ho latela litlhoko tse fapaneng tsa tlhahiso le melao-motheo ea ts'ebetso, e loketseng lisebelisoa tse fapaneng le mefuta ea lihlahisoa.Ho khetha le ho kopanya lits'ebetso tsena ka nepo ho ka khotsofatsa litlhoko tsa mekhoa e fapaneng ea tlhahiso.Empa bakeng sa ho hatella lisebelisoa tse tala, ho ipapisitse le boiphihlelo ba lilemo tse mashome, re khothaletsa mechini ea khatiso e chesang ea welding:

1. Sebopeho sa ka hare sa ho lahla se batla se hlephile, se na le matla a tlaase, 'me se ke ke sa mamella khatello e phahameng.Likarolo tsa welding li na le matla a phahameng, ntlha e eketsehileng ea polokeho 'me li ka mamella khatello e kholoanyane.Ka mor'a ho theha, likarolo tsa welding li tiile ka hare 'me li ke ke tsa hlahisa likoti kapa mapetsong.

2. Likarolo tse ka hare tsa li-castings li atisa ho hlahisa li-pores kapa li-pinholes, tse ka 'nang tsa tsoa butle-butle nakong ea tšebeliso.

Kaha tlhahiso ea li-brake pads e hloka tekanyo e itseng ea ho nepahala ha ho hatelloa ho chesang, kahoo mechine ea ho hatisa e ntse e khothalletsoa haholoanyane.

Litlhahiso tse nyane:

E le ho etsa hore brake pad e 'ngoe le e' ngoe e fumane khatello e lekaneng, 'me ka li-cavities tse ngata le litšenyehelo tse tlaase tsa ho hlahisa li-brake pads, hangata li-brake pads li sebelisa mochine o fapaneng oa khatiso ka Lithane:

Lithuthuthu brake pads- 200/300 Ton

Li-brake pads - 300/400 Ton

Li-brake pads tsa likoloi tsa khoebo -400 Ton

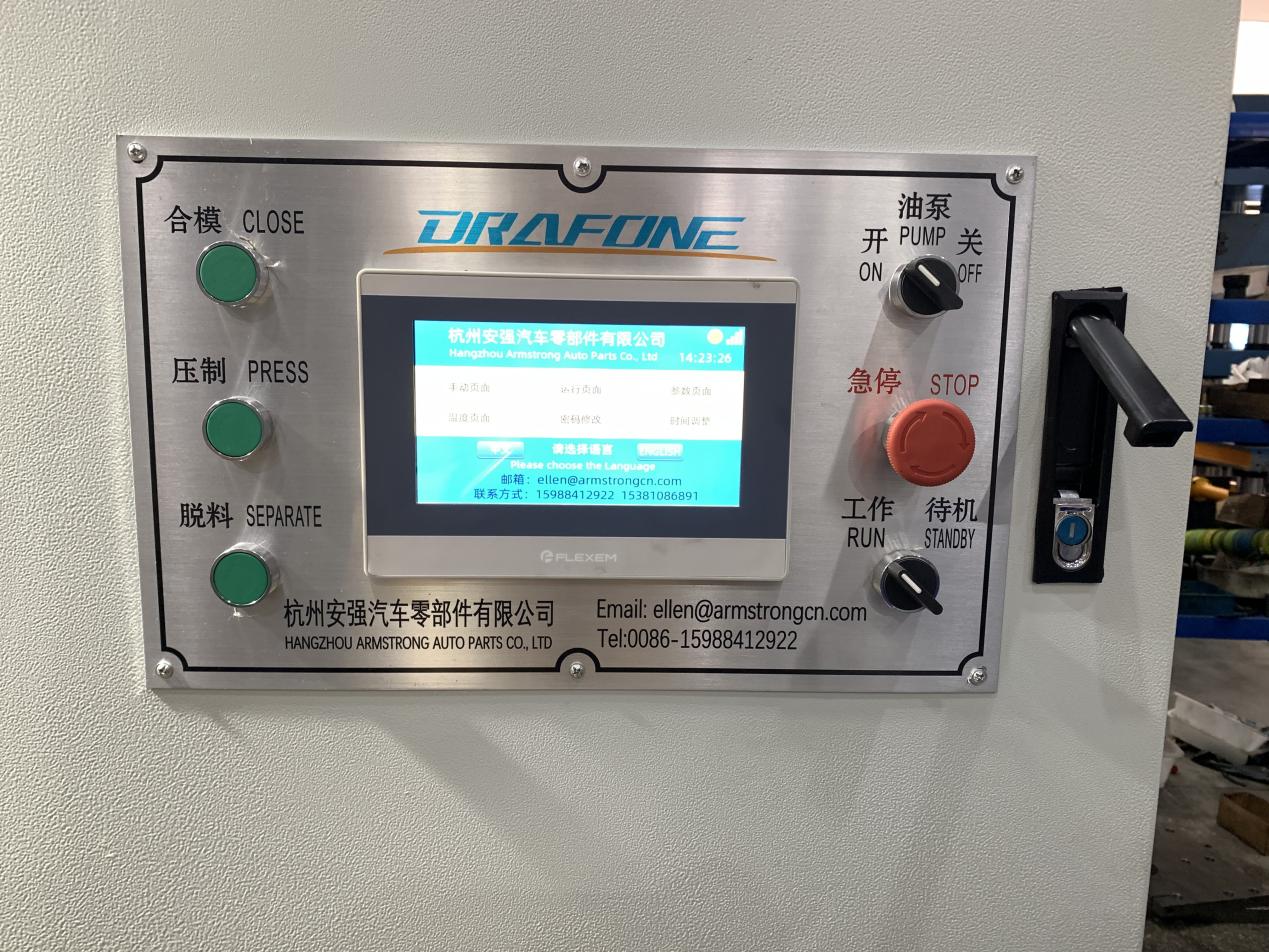

(Mofuta oa khatiso o chesang)

Nako ea poso: Jun-26-2023